Crusader002

Cadet

- Joined

- Dec 19, 2011

- Messages

- 23

Long timer lurker, first time poster here. So glad you all could take my call! Ahem... down to business. Below is the beauty. A 1973 Super Sport last registered in 1989. She sports a matching model year Johnson 65hp and sits on a trailer that is in serviceable shape but likely destined for a swap with another member of the fleet.

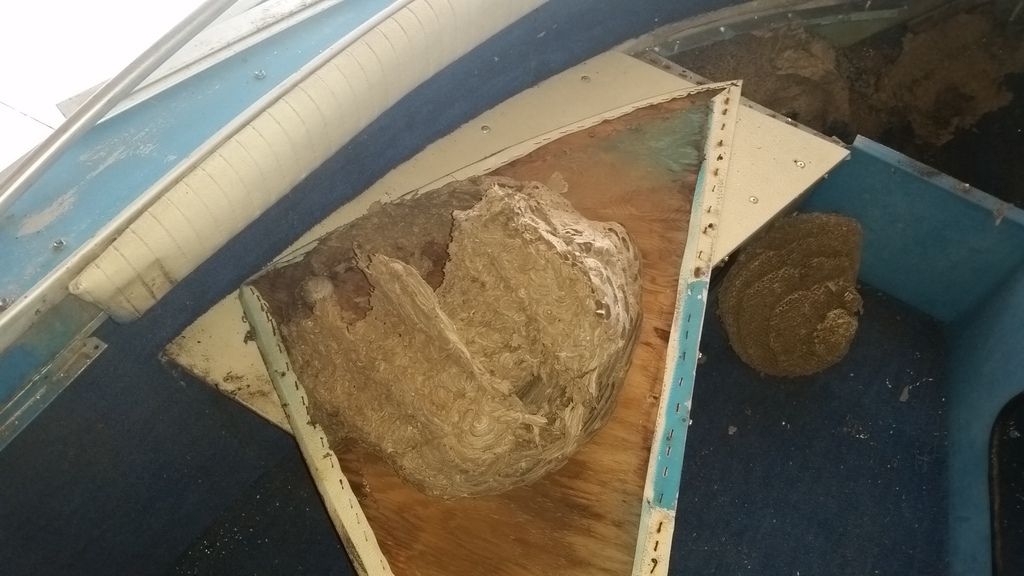

The boat came from a friend of mine who was the second owner and his brother owned it before him. He takes good care of his toys, but 25+ years of sitting outside (even under a heavy duty tarp) will do some damage. The old girl needs some new timber and a good cleaning. Thankfully, Scott and I have killed most of the wasps and other stinging insects that have taken residence in the boat over the years leaving behind the signs of their people. Aside from the bees, water has managed to infiltrate the wood in the back third of the boat. Its new home inside a garage and a hot summer left uncovered allowed it to dry out, but it left behind dry, spongy wood in the floor and transom. And quite a few mushrooms...

Currently, the plan is to replace the transom, get the motor running again, get the floor sorted out and take it for a spin before I add any weight or make changes so I have an idea of how I am impacting how the vessel handles in the water. The plan is to keep the SS as "original" as possible, but make it more fishing friendly.

Progress thus far:

Still have a ways to go, but progress is progress on a project like this. Ultimate goal is to add a livewell (or two), trolling motor, depth finder, fore and aft fishing platforms, seating (still deciding exactly how I want to accomplish this), mount my 9.9 Evinrude, add a CNC TNT unit, and rod storage underfloor (similar to Huron Angler). I have been scrounging as I go and have quite a few parts and pieces already. Now I just need to finish up that demo!

The good news is the Admiral approves and has been helping get the craft back on the water. And to the mob out there, don't worry... I have plenty more pictures taken and coming. I'm sure I'll have questions as I go and some pictures to showcase my backwoods ingenuity. Until then, I can think of the day this picture is taken on the water and not in the barn.

The boat came from a friend of mine who was the second owner and his brother owned it before him. He takes good care of his toys, but 25+ years of sitting outside (even under a heavy duty tarp) will do some damage. The old girl needs some new timber and a good cleaning. Thankfully, Scott and I have killed most of the wasps and other stinging insects that have taken residence in the boat over the years leaving behind the signs of their people. Aside from the bees, water has managed to infiltrate the wood in the back third of the boat. Its new home inside a garage and a hot summer left uncovered allowed it to dry out, but it left behind dry, spongy wood in the floor and transom. And quite a few mushrooms...

Currently, the plan is to replace the transom, get the motor running again, get the floor sorted out and take it for a spin before I add any weight or make changes so I have an idea of how I am impacting how the vessel handles in the water. The plan is to keep the SS as "original" as possible, but make it more fishing friendly.

Progress thus far:

- Exterior of the boat and interior vinyl thoroughly cleaned with a soap/bleach solution to remove quite a bit of black mold, dirt, and algae

- Controls disconnected from the motor. Began disconnecting the control box and navigating the wiring that has been added to it over the years

- Motor stand built and the Johnson has been relocated. Let's just say that plan A did not go as anticipated and a bear hug and some swearing later the job was done.

- Started removal of transom trim pieces and any hardware bolted on or through the transom in preparation for removal of the mulch within (see below)

Still have a ways to go, but progress is progress on a project like this. Ultimate goal is to add a livewell (or two), trolling motor, depth finder, fore and aft fishing platforms, seating (still deciding exactly how I want to accomplish this), mount my 9.9 Evinrude, add a CNC TNT unit, and rod storage underfloor (similar to Huron Angler). I have been scrounging as I go and have quite a few parts and pieces already. Now I just need to finish up that demo!

The good news is the Admiral approves and has been helping get the craft back on the water. And to the mob out there, don't worry... I have plenty more pictures taken and coming. I'm sure I'll have questions as I go and some pictures to showcase my backwoods ingenuity. Until then, I can think of the day this picture is taken on the water and not in the barn.