Hi Jimbotek, and welcome to the iboats Startmada forums. It would be great to keep track with each other?s progress. Pics are great. The people here love them and it does really help, both the posters when posting and asking questions and for readers (such as ourselves) learning about what people are doing.

I am with you on the once gutted, checking to find leaks. Being a wee bit anal on occasion, I may put it in the canal first to check, and then pull and fill partially (as you suggest) for a second check. I wasn't sure if there was any chance that the boat weight on the trailer could push / hide any issues where the hull and trailer are in contact.

My current intention is to go with non pressure treated plywood. It seems the pressure treatment uses a lot of chemicals that would be detrimental. I may use marine, but I have seen alot of others talk about using slightly lower grades and basically massively sealing/expoxy the wood. I take it you used marine plywood. What did you use/do for sealing it?

I also have a curiosity on what synthetic materials may be available these days, their costs and characteristics. The idea(l) of never rotting does have appeal. From what I have seen, there may be plastics or composites around. They seem to be 2x and up in costs. The plastics appear to get really hot if in warm sunny environments. This may not be such an issue for me and my primary boat usage in northern Ontario and a bit here in upstate NY. (Although if the global warming keeps moving along, who knows, we may even end up with a couple sunny days.) The composites will still absorb water, the aeration underneath (or lack of it I should say), and robustness to something like power washing look to be issues there. Most likely, I will just go with the plywood.

Looking around at the new boats on the market, it seems a lot of them come with vinyl deck covering instead of just carpet. I like this idea a lot, especially since my passion is northern pike fishing. Pike are extremely slimy, and managing the slim on the carpet (or not managing it and the stink) is a new issue for me as I am coming from a bare steel hull craft. My wife likes the idea of just being able to spray the slime off the deck (or back to a spot where a bilge could get it.)

Is your current SS project a 16? or 18??

2 1/2 hrs to Balston Spa would put you near Plattsburg if to the North or Syracuse if to the West.

For 45 years I have fished out of a trusty 14' plate steel logging boat.

For 45 years I have fished out of a trusty 14' plate steel logging boat.

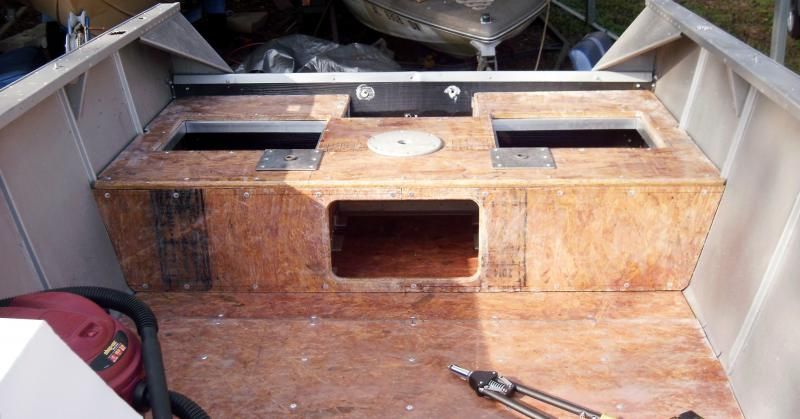

She's pretty scratched up. The floor is soft in the middle from the front to the back, so I am guessing it is a gut and rebuild. I would like to redesign the front deck area, the rear area around the splash pan and also put in a significant livewell.

She's pretty scratched up. The floor is soft in the middle from the front to the back, so I am guessing it is a gut and rebuild. I would like to redesign the front deck area, the rear area around the splash pan and also put in a significant livewell.