mirrocraft16

Seaman Apprentice

- Joined

- Oct 1, 2014

- Messages

- 36

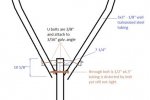

I have two boat trailers, both are built the same way, with a single 3x3" tongue and two 2x3" side frame rails joined in the middle with a single 1/2" bolt and two U bolts through a piece of angle iron about a foot behind the first bolt.

If I put any weight on the rear of the trailer, empty or loaded, the tongue to frame joint flexes about 4". The one trailer is brand new, the other one a few years old. I can't tighten anything up anymore without crushing tubing. What I don't like is that it no doubt flexes going down the road.

It just seems that the tongue should have gone all the way to the first cross member not just 12" past the first bolt.

I have no doubt that with time and movement the 1/2" bolt will eventually cut through the tubing, its already starting to tear or distort the tubing where its forced to conform to the angle of the joint.

The pic here is the style frame and almost identical trailer: The boat don't weight much, its just a 14' aluminum boat on it but with the bow secured to the winch post and the transom tied to the rear cross member, the frame has to be bouncing up and down under the boat. It almost seems like there should be a triangle shaped plate bolted over that joint to tie everything together. Every trailer this size I looked at used this design.

If I put any weight on the rear of the trailer, empty or loaded, the tongue to frame joint flexes about 4". The one trailer is brand new, the other one a few years old. I can't tighten anything up anymore without crushing tubing. What I don't like is that it no doubt flexes going down the road.

It just seems that the tongue should have gone all the way to the first cross member not just 12" past the first bolt.

I have no doubt that with time and movement the 1/2" bolt will eventually cut through the tubing, its already starting to tear or distort the tubing where its forced to conform to the angle of the joint.

The pic here is the style frame and almost identical trailer: The boat don't weight much, its just a 14' aluminum boat on it but with the bow secured to the winch post and the transom tied to the rear cross member, the frame has to be bouncing up and down under the boat. It almost seems like there should be a triangle shaped plate bolted over that joint to tie everything together. Every trailer this size I looked at used this design.