Yes, this is my first post, but I have trolled on here before concerning issued with outboards and solved my problems through the members posts.

Picked up our first family boat this past weekend.

Some info from stickers/plates:

Outdrive:

Prod#- 3868035

Type- SX

Ratio- 185

Ser- 4112003668

Engine Data #'s (idk what they mean):

4110102490

38680034

3.0GSPMDA

Technical data

Engine 3.0GSPMDA

Production period 1993-1994

Operation 4-stroke

Cylinder configuration 4

Bore (mm) 101.6

Stroke (mm) 91.4

Compression ratio 9.31:1

Displacement (litres) 2.96

Power (hp) 150

Max engine speed (rpm) 4200-4600

Started boat for first time (in garage w muffs on w engine cover off).

Started good, idled well enough for the 30 seconds I had it running until I noticed that the water pump belt was spinning, but the pully wasn't and then I shut it down (there was a loud chirping noise as well).

I know what you're thinking... tighten the belt... ya ya I did.

Started it again to see...

Water Pump Pulley not spinning.

Alternator Pump not spinning (appeared to be trying).

Servo (??) Pump pulley spinning but making a RACKET (this is where I think the noise is coming from).

Can I replace just the servo pulley/bearings? Where Can I find them?

Is this keeping all the other belts from spinning?

I can turn the water pump pulley by hand, although it takes quite a bit of force.

Didn't try the alternator pulley.

Servo (??) Pump has fluid.

Additionally, and this may solve the problem in itself.

If I crank it just a lil' bit and stop, all the belts will spin as the engine settles(although I do think its in reverse from the engine removing itself from a compression stroke). This in itself makes me think it needs new belts, and the pulleys cleaned up.

But I still have the noise to isolate and correct as well.

Worst case scenario I'll have it checked out by a local shop, but I really don't have the money, and was hoping someone with experience/knowledge could try to walk me through this - or come lend a hand if your close (or I can come to you... with beverages of course).

I've downloaded the owners manual, and browsed some service manual online.

Once this is solved, I'll get into fixing the issue with the outdrive lowering itself over time.

Anyone care to help me get on the water?

Thanks in advance!

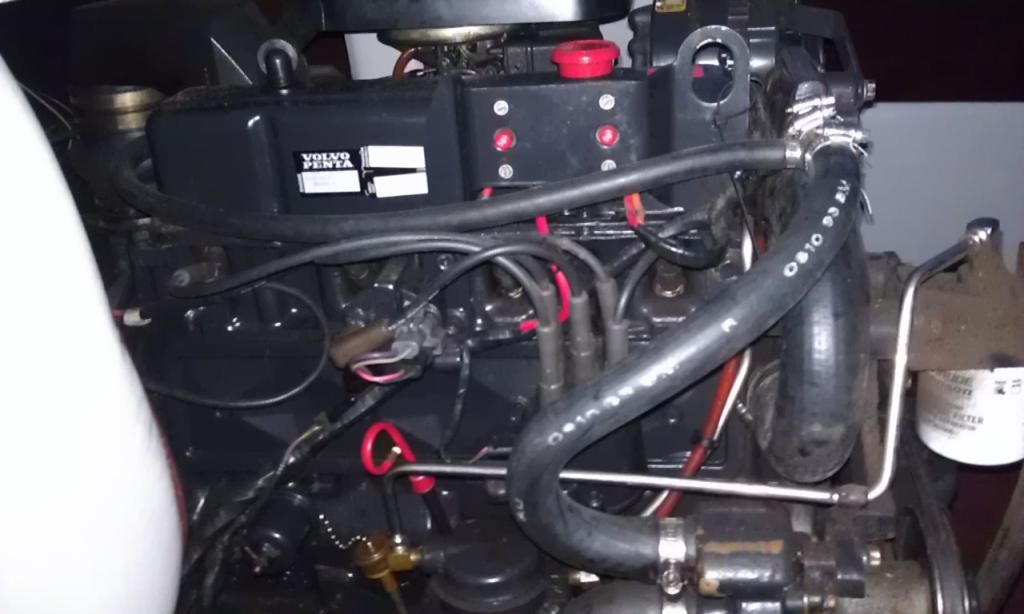

In case I am using the wrong terms the middle two pulleys, and the bottom right (I think the noisy one) are the only pulleys really moving.

Picked up our first family boat this past weekend.

Some info from stickers/plates:

Outdrive:

Prod#- 3868035

Type- SX

Ratio- 185

Ser- 4112003668

Engine Data #'s (idk what they mean):

4110102490

38680034

3.0GSPMDA

Technical data

Engine 3.0GSPMDA

Production period 1993-1994

Operation 4-stroke

Cylinder configuration 4

Bore (mm) 101.6

Stroke (mm) 91.4

Compression ratio 9.31:1

Displacement (litres) 2.96

Power (hp) 150

Max engine speed (rpm) 4200-4600

Started boat for first time (in garage w muffs on w engine cover off).

Started good, idled well enough for the 30 seconds I had it running until I noticed that the water pump belt was spinning, but the pully wasn't and then I shut it down (there was a loud chirping noise as well).

I know what you're thinking... tighten the belt... ya ya I did.

Started it again to see...

Water Pump Pulley not spinning.

Alternator Pump not spinning (appeared to be trying).

Servo (??) Pump pulley spinning but making a RACKET (this is where I think the noise is coming from).

Can I replace just the servo pulley/bearings? Where Can I find them?

Is this keeping all the other belts from spinning?

I can turn the water pump pulley by hand, although it takes quite a bit of force.

Didn't try the alternator pulley.

Servo (??) Pump has fluid.

Additionally, and this may solve the problem in itself.

If I crank it just a lil' bit and stop, all the belts will spin as the engine settles(although I do think its in reverse from the engine removing itself from a compression stroke). This in itself makes me think it needs new belts, and the pulleys cleaned up.

But I still have the noise to isolate and correct as well.

Worst case scenario I'll have it checked out by a local shop, but I really don't have the money, and was hoping someone with experience/knowledge could try to walk me through this - or come lend a hand if your close (or I can come to you... with beverages of course).

I've downloaded the owners manual, and browsed some service manual online.

Once this is solved, I'll get into fixing the issue with the outdrive lowering itself over time.

Anyone care to help me get on the water?

Thanks in advance!

In case I am using the wrong terms the middle two pulleys, and the bottom right (I think the noisy one) are the only pulleys really moving.