Hi all,

I have 1999 Volvo Penta 5.0Gi (PWTR series engine, Throttle Body Injection) with 634 hours. For the last 2 seasons its been running rich causing a blackish film on the transom and a increase in fuel smell idling, after about 15hrs on an oil change I can begin to smell fuel in the oil.

It does run virtually without issue. Starts right up, idles well (never stalls or dies, but I do notice it missing) and can run up to WOT and anywhere in between perfectly. So while I probably should just be happy and keep boating, it does continue to bother me.

So far I have done the following 2 years ago:

1. Replaced Cap and Rotor

2. New OEM Volvo Plug wires

3. New MAP and Engine Coolant sensors

4. New PCV

5. New IAC

6. New Plugs (done seasonly in the spring)

This spring the following was done:

1. Fuel Pressure test

- Low side 5psi

- High side 29.5-30psi idle

Both are almost dead on spec.

2. Compression test

- Engine run to operating temp, Plugs out, throttle wide open, fuel system disabled, ignition disabled. All cylinders were 182psi-189psi

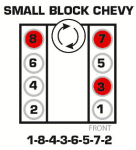

So what I did notice when I pulled the plugs (which were brand new and only run for about 45min-1hr idling-1300rpm on muffs) to do the compression test is that 3 of them were much more fouled, while the other 5 looked just fine.

Here are two pictures of the plugs, plugs are in order,

The first is the Port side and the second is the Starboard Side. Left most plugs are the Front cylinders, Right most are the rear cylinders.

Any thoughts on where I should go forward? Im thinking of checking the ignition system, given that only 3 plugs seem to be much richer. Would a leaky injector be able to do that?

I have 1999 Volvo Penta 5.0Gi (PWTR series engine, Throttle Body Injection) with 634 hours. For the last 2 seasons its been running rich causing a blackish film on the transom and a increase in fuel smell idling, after about 15hrs on an oil change I can begin to smell fuel in the oil.

It does run virtually without issue. Starts right up, idles well (never stalls or dies, but I do notice it missing) and can run up to WOT and anywhere in between perfectly. So while I probably should just be happy and keep boating, it does continue to bother me.

So far I have done the following 2 years ago:

1. Replaced Cap and Rotor

2. New OEM Volvo Plug wires

3. New MAP and Engine Coolant sensors

4. New PCV

5. New IAC

6. New Plugs (done seasonly in the spring)

This spring the following was done:

1. Fuel Pressure test

- Low side 5psi

- High side 29.5-30psi idle

Both are almost dead on spec.

2. Compression test

- Engine run to operating temp, Plugs out, throttle wide open, fuel system disabled, ignition disabled. All cylinders were 182psi-189psi

So what I did notice when I pulled the plugs (which were brand new and only run for about 45min-1hr idling-1300rpm on muffs) to do the compression test is that 3 of them were much more fouled, while the other 5 looked just fine.

Here are two pictures of the plugs, plugs are in order,

The first is the Port side and the second is the Starboard Side. Left most plugs are the Front cylinders, Right most are the rear cylinders.

Any thoughts on where I should go forward? Im thinking of checking the ignition system, given that only 3 plugs seem to be much richer. Would a leaky injector be able to do that?

Attachments

Last edited: