stancalame

Petty Officer 2nd Class

- Joined

- May 10, 2014

- Messages

- 113

I keep coming back to the well! The last time boat was out I noticed that it periodically would not go into neutral right away with shidter in nuetral position. I could move toward reverse and back to neutral and it I could feelI it go to Neutral. I assume this is a linkage adjustment and I have read the manual on how to do it so I am goof wetih that procedure. My questions are:

1)What would cause this to happen? Boat has shifted into and out of forward however the issue seems to have gotten worse over time. It used to delay for afew seconds then come out of gear.

2) I have my outdrive off for maintenance and dont see anything wrong with lower shift mechanism however I'm not sure what to look for. Should I put lower unit back together first and then address shifting issue or is there something I should check while I've got it apart? It would be a real pain to have the pull the out drive right back off.

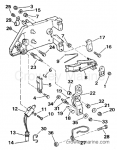

Boat has OMC 574AERGD with King Cobra Stern Drive. I've been told I have a cone clutch because my drive has the dipstick at the top and fill port on the bottom. That does not mean anything to me and I dont know if that is accurate but thought it might be helpful in diagnosing the shifting issue. Appreciate any insght you may have.

1)What would cause this to happen? Boat has shifted into and out of forward however the issue seems to have gotten worse over time. It used to delay for afew seconds then come out of gear.

2) I have my outdrive off for maintenance and dont see anything wrong with lower shift mechanism however I'm not sure what to look for. Should I put lower unit back together first and then address shifting issue or is there something I should check while I've got it apart? It would be a real pain to have the pull the out drive right back off.

Boat has OMC 574AERGD with King Cobra Stern Drive. I've been told I have a cone clutch because my drive has the dipstick at the top and fill port on the bottom. That does not mean anything to me and I dont know if that is accurate but thought it might be helpful in diagnosing the shifting issue. Appreciate any insght you may have.