hkeiner

Lieutenant Junior Grade

- Joined

- Oct 17, 2006

- Messages

- 1,055

I have a 1996 150 HP Mercury OB (serial OG397853). It starts fine when cold, runs well at WOT, and idles well (without smoke) when I slow down to low speed or neutral after running at WOT. However, the motor does not like to start again in neutral when the engine has been turned off for a few minutes (or more) when the engine is warm. Here are the symptoms I have identified:

1) It won't start in neutral and seems to be either flooded or overloaded with oil.

2) I have to advance the throttle lever to medium/low throttle (with side button pushed in so it does not go into gear) for it to start

3) I have to keep it running at medium/low throttle until the gas/oil burns off (say for 15-30 seconds) with a lot of smoke .

4) The engine dies if I pull the throttle back to idle position and I didn't wait until the heavy smoke stops coming out of the exhaust at medum/low throttle.

5) All six spark plugs are equally very oily when I remove them.

6) There is an accumulation of oil at the bottom of the cowel below the carbs, as if oil runs out of the carb barrels when the engine is tilted forward.

7) None of the gas or oil hoses appear to be leaking.

8 ) The bottom of all six carb barrels are oily with some of them having an accumulation of oil on them

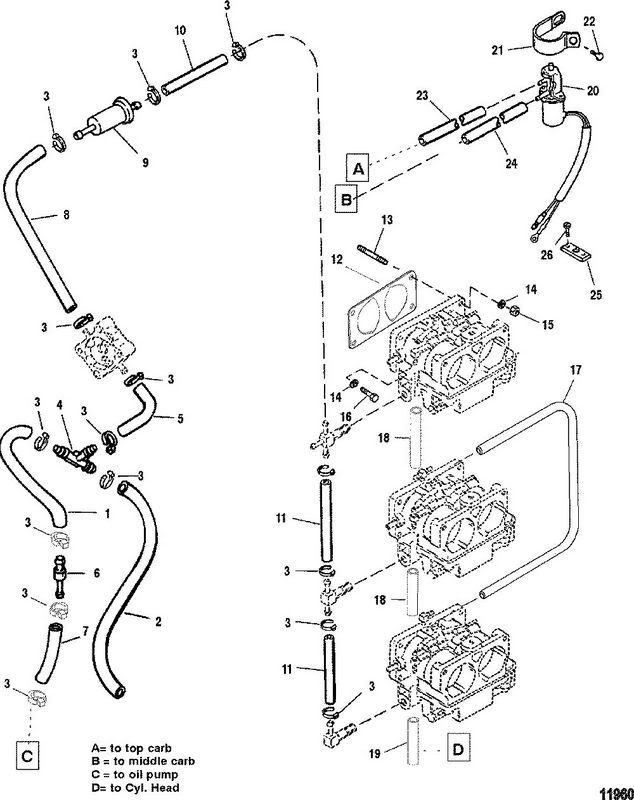

I have read some old posts suggesting that excess oil may being forced into the carbs (after the engine is turned off) if the pressure in the oil injection system is not automatically relieved due to a faulty check valve. It was not clear, however, how to fix this problem or which check valve may be the culprit. Based upon the system diagrams for my motor, there appears to be three check valves in the fuel/oil injection system. None of these, however, are described as being for the purpose of relieving the oil injection system's pressure. The three check valves are described as having the following purposes:

A) One 2psi check valve avoids a vacuum in the top reservoir if oil flow to the reservoir is obstructed.

B) The second 2psi check valve is to avoid fuel being forced into the oil lines.

C) The third check valve regulates the crankcase pressure going to the remote oil tank.

Any thoughts on this? Should I just replace all three check valves and see what happens? I would like to avoid spending the money to get the carbs rebuilt until I have tried some easier/less expensive/more likely solutions myself.

1) It won't start in neutral and seems to be either flooded or overloaded with oil.

2) I have to advance the throttle lever to medium/low throttle (with side button pushed in so it does not go into gear) for it to start

3) I have to keep it running at medium/low throttle until the gas/oil burns off (say for 15-30 seconds) with a lot of smoke .

4) The engine dies if I pull the throttle back to idle position and I didn't wait until the heavy smoke stops coming out of the exhaust at medum/low throttle.

5) All six spark plugs are equally very oily when I remove them.

6) There is an accumulation of oil at the bottom of the cowel below the carbs, as if oil runs out of the carb barrels when the engine is tilted forward.

7) None of the gas or oil hoses appear to be leaking.

8 ) The bottom of all six carb barrels are oily with some of them having an accumulation of oil on them

I have read some old posts suggesting that excess oil may being forced into the carbs (after the engine is turned off) if the pressure in the oil injection system is not automatically relieved due to a faulty check valve. It was not clear, however, how to fix this problem or which check valve may be the culprit. Based upon the system diagrams for my motor, there appears to be three check valves in the fuel/oil injection system. None of these, however, are described as being for the purpose of relieving the oil injection system's pressure. The three check valves are described as having the following purposes:

A) One 2psi check valve avoids a vacuum in the top reservoir if oil flow to the reservoir is obstructed.

B) The second 2psi check valve is to avoid fuel being forced into the oil lines.

C) The third check valve regulates the crankcase pressure going to the remote oil tank.

Any thoughts on this? Should I just replace all three check valves and see what happens? I would like to avoid spending the money to get the carbs rebuilt until I have tried some easier/less expensive/more likely solutions myself.

Last edited: