- Joined

- Jul 18, 2011

- Messages

- 17,696

I have a 1969 Mercury 7.5 HP outboard that I use for my dinghy/tender. It seems to be seeping through the gaskets around the water jackets over the past couple of years. So I thought I would do a refresh of the motor and share some pictures of the project. I also plan on a bit of cosmetic work, re-painting and new stickers on the engine cowl, etc.

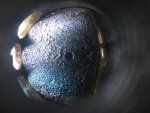

The spark plugs at the end of the season looked remarkably clean . . . too clean . . . so my thoughts were that water was getting into the cylinders. However, based on the design of this engine, I'm not sure how water would get into the cylinders, unless it were reversion from the exhaust at the bottom of the power stroke. . . but I'm not even sure that would apply to a 2-cycle engine, since the intake side is under pressure at that point :noidea:

Anywhere else that I should look for water getting into the combustion process? Salt water BTW. . .

Anything else that would result in such clean plugs?

I started tearing the engine down, at least the water jackets, as that is where the corrosion is showing up The side panel was pretty easy . . . only snapped the head of 2 of the bolts

Lots of salt/calcium build up in these water passages . . . So, I probably need to do a CLR flush after each season.

The cylinder cover plate . . . not so easy. I was able to get 1 screw/stud out intact. The rest had to be drilled out. I drilled through the head of the Phillips bolt until the head broke off. This allowed me to pull the cover plate off and then I could try to back out the remains of the bolts. . . . at least that was the plan.

The gasket holding the cover plate on had different ideas and it took a lot of tricky cutting work to be able to get enough of the gasket separated in order to get some leverage to pry the plate off. I was concerned about breaking the plate in two, if I applied too much force in one area.

Here is the plate with the bolt heads drilled out

Here is the cover plate once it finally gave up . . .

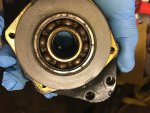

Here is the innerds of the cylinders with integral cylinder head. A very 'cool' design for a 1969 motor, as there is no separate cylinder head and the top of the cylinder is surrounded in the cooling water.

There is also a smaller plate on the other side of the engine that covers the intake ports. That plate seems fine, so my plan is to leave it alone, unless someone has reason that I should remove it :noidea:

I have prepped the cowl and the external surfaces of the engine for re-painting. I found a set of re-production decals online that I ordered. So, hopefully I can make the engine look and act like new again.

FWIW - a year or 2 ago, I replaced the carbon steel drive shaft on this motor with a stainless steel shaft from a 1980 motor . . . yea it had not changed much over the course of the 1970's.

Anyway, my main concern right now is if I am missing something as to how the spark plugs are getting so clean ???

. . . the first picture is how they looked when I took them out of the engine. Last year, only the bottom plug was showing signs of cleanliness, this year it is both plugs.

The spark plugs at the end of the season looked remarkably clean . . . too clean . . . so my thoughts were that water was getting into the cylinders. However, based on the design of this engine, I'm not sure how water would get into the cylinders, unless it were reversion from the exhaust at the bottom of the power stroke. . . but I'm not even sure that would apply to a 2-cycle engine, since the intake side is under pressure at that point :noidea:

Anywhere else that I should look for water getting into the combustion process? Salt water BTW. . .

Anything else that would result in such clean plugs?

I started tearing the engine down, at least the water jackets, as that is where the corrosion is showing up The side panel was pretty easy . . . only snapped the head of 2 of the bolts

Lots of salt/calcium build up in these water passages . . . So, I probably need to do a CLR flush after each season.

The cylinder cover plate . . . not so easy. I was able to get 1 screw/stud out intact. The rest had to be drilled out. I drilled through the head of the Phillips bolt until the head broke off. This allowed me to pull the cover plate off and then I could try to back out the remains of the bolts. . . . at least that was the plan.

The gasket holding the cover plate on had different ideas and it took a lot of tricky cutting work to be able to get enough of the gasket separated in order to get some leverage to pry the plate off. I was concerned about breaking the plate in two, if I applied too much force in one area.

Here is the plate with the bolt heads drilled out

Here is the cover plate once it finally gave up . . .

Here is the innerds of the cylinders with integral cylinder head. A very 'cool' design for a 1969 motor, as there is no separate cylinder head and the top of the cylinder is surrounded in the cooling water.

There is also a smaller plate on the other side of the engine that covers the intake ports. That plate seems fine, so my plan is to leave it alone, unless someone has reason that I should remove it :noidea:

I have prepped the cowl and the external surfaces of the engine for re-painting. I found a set of re-production decals online that I ordered. So, hopefully I can make the engine look and act like new again.

FWIW - a year or 2 ago, I replaced the carbon steel drive shaft on this motor with a stainless steel shaft from a 1980 motor . . . yea it had not changed much over the course of the 1970's.

Anyway, my main concern right now is if I am missing something as to how the spark plugs are getting so clean ???

. . . the first picture is how they looked when I took them out of the engine. Last year, only the bottom plug was showing signs of cleanliness, this year it is both plugs.