Good Morning!

With the help I have got here, Service manual 14, and the seloc manual, I am just about there!

I was even able to get rolling torque right on the SECOND try!

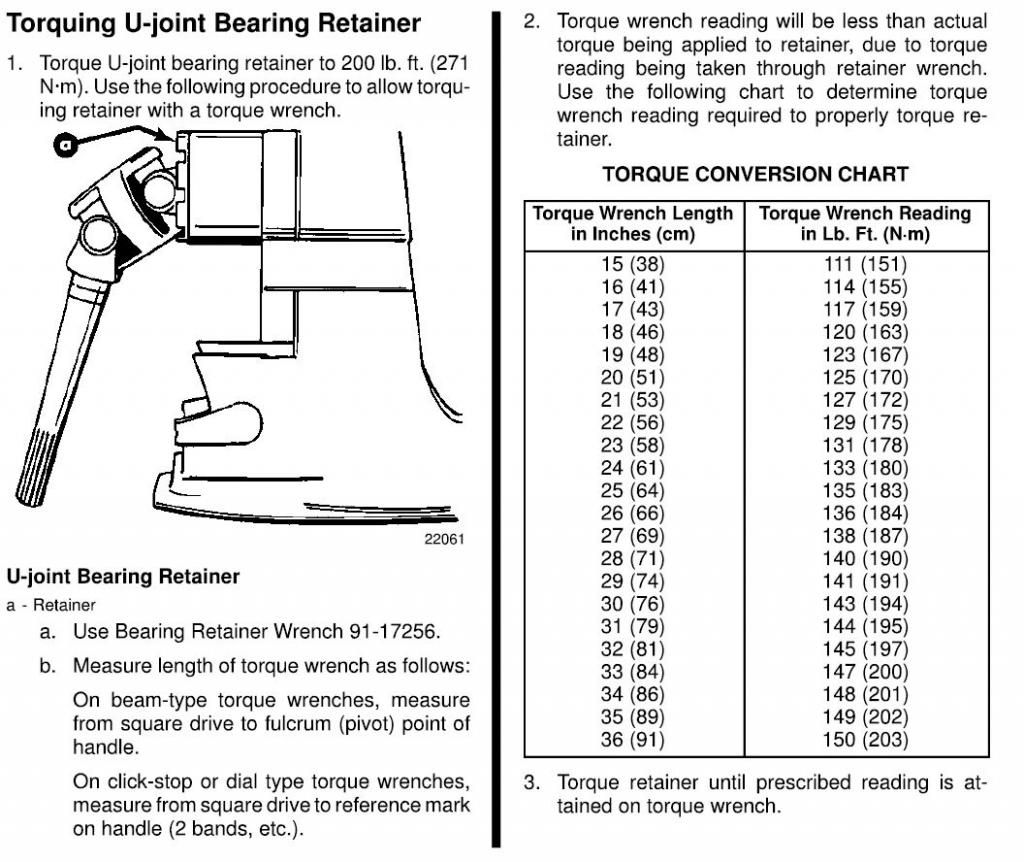

I have a question on the retainer nut...... I know spec is 200 ft/lbs or 120 if using the wrench with a torque wrench in the square hole....... I have gotten the nut to the limit of my 100 ft/lbs torque wrench and hit it a few times with a mallet to ensure it was where it should be. The problem is that I still can see a couple threads of the retainer nut. All of the images that I have viewed online seem to show it flush in the housing.

Does this mean that I am not truly to the proper torque and that no threads should be showing? Does it mean I might have done something else wrong?

Or is it nothing and I am just worrying too much?

With the help I have got here, Service manual 14, and the seloc manual, I am just about there!

I was even able to get rolling torque right on the SECOND try!

I have a question on the retainer nut...... I know spec is 200 ft/lbs or 120 if using the wrench with a torque wrench in the square hole....... I have gotten the nut to the limit of my 100 ft/lbs torque wrench and hit it a few times with a mallet to ensure it was where it should be. The problem is that I still can see a couple threads of the retainer nut. All of the images that I have viewed online seem to show it flush in the housing.

Does this mean that I am not truly to the proper torque and that no threads should be showing? Does it mean I might have done something else wrong?

Or is it nothing and I am just worrying too much?