Delmagtech

Seaman Apprentice

- Joined

- Jul 7, 2014

- Messages

- 35

I have a friends boat coming to me this evening to look at, and I've been doing some research on-line as to what's going on. I thought I would post about it here to see if anyone has been where I'm going.

The boat is an 01 Caravelle 176 with a Mercruiser MCM 3.0 / Alpha.

A month ago, she took this boat to her normal guy for maintenece. He apparently fixed some problem with the nuetral button in the shifter. She took the boat out, and about the time she engaged WOT, it died. Once it died, it wouldn't start again. She brought it back. He figured out that the ign. module was bad. He put one in from another boat, and it fried it almost immediately. He knew it was fried because it wouldn't work when he put back in the original boat.

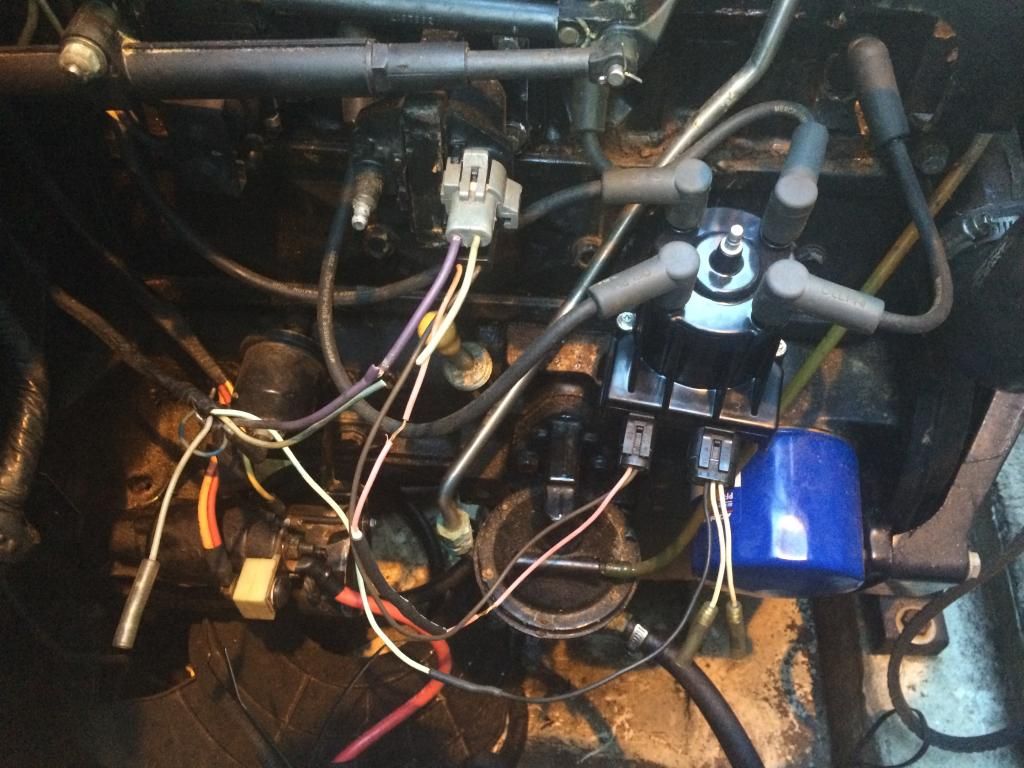

He sent her to mech #2. Mech #2 replaced module, and fried it himself. Then he said that the gray signal wire going to the tach was shorted, and causing the module failure. Fixed said short in gray wire, installed another module and sent her on her way. She took it on vacation, got if off the trailer, went WOT and it's fried again.

She took the boat to a third mech in the vacation city, he installed a new module, and it was more of the same. It's been on the trailer since.

So now, I'm going to give it a try.

I've read that bad / corroded battery cables can create current spikes that cause big problems for the module, so I'll be looking at that first. Seems along that line of thought cleaning up grounds might be just as important.

The problem seemed to start when the guy fixed something with the nuetral button in the shifter. I can look at that as well, but I've not read a single post where problems with the electrical switch in the shifter (I assume this pulls timing while going in / out of gear) caused damage to the module.

Lastly, I'll check out this gray signal wire going to the tach, but here again, I've read plenty of posts about tach problems, some even claiming a bad tach kept the engine from running, but none yet about permanent damage to the module.

It's a little baffling as the system seems relatively simple. She says with a new module it will cold start and idle all day. But as soon as she opens it up, it's done. Sometimes, after sitting all night, the boat will start again.

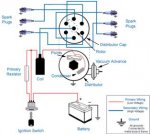

I'm wondering if the ignition coil is shorting out when it gets warm or is asked for full load. Im also curious as to whether a problem with the pickup coil could cause issue here. Lastly, I see the cable that connects the module to the coil is pretty pricey, which leads me to think it might more than just a pair of wires. Diodes, resistors or anything else in there prone to this problem?

If you guys have any pointers for me, I'd sure appreciate it. I'm going to start with battery cables and looking at the switch in the shifter.

The boat is an 01 Caravelle 176 with a Mercruiser MCM 3.0 / Alpha.

A month ago, she took this boat to her normal guy for maintenece. He apparently fixed some problem with the nuetral button in the shifter. She took the boat out, and about the time she engaged WOT, it died. Once it died, it wouldn't start again. She brought it back. He figured out that the ign. module was bad. He put one in from another boat, and it fried it almost immediately. He knew it was fried because it wouldn't work when he put back in the original boat.

He sent her to mech #2. Mech #2 replaced module, and fried it himself. Then he said that the gray signal wire going to the tach was shorted, and causing the module failure. Fixed said short in gray wire, installed another module and sent her on her way. She took it on vacation, got if off the trailer, went WOT and it's fried again.

She took the boat to a third mech in the vacation city, he installed a new module, and it was more of the same. It's been on the trailer since.

So now, I'm going to give it a try.

I've read that bad / corroded battery cables can create current spikes that cause big problems for the module, so I'll be looking at that first. Seems along that line of thought cleaning up grounds might be just as important.

The problem seemed to start when the guy fixed something with the nuetral button in the shifter. I can look at that as well, but I've not read a single post where problems with the electrical switch in the shifter (I assume this pulls timing while going in / out of gear) caused damage to the module.

Lastly, I'll check out this gray signal wire going to the tach, but here again, I've read plenty of posts about tach problems, some even claiming a bad tach kept the engine from running, but none yet about permanent damage to the module.

It's a little baffling as the system seems relatively simple. She says with a new module it will cold start and idle all day. But as soon as she opens it up, it's done. Sometimes, after sitting all night, the boat will start again.

I'm wondering if the ignition coil is shorting out when it gets warm or is asked for full load. Im also curious as to whether a problem with the pickup coil could cause issue here. Lastly, I see the cable that connects the module to the coil is pretty pricey, which leads me to think it might more than just a pair of wires. Diodes, resistors or anything else in there prone to this problem?

If you guys have any pointers for me, I'd sure appreciate it. I'm going to start with battery cables and looking at the switch in the shifter.