Re: 5.7 Vortec 2BBL to 350 Mag MPI Conversion

Alright one step forward and two steps back.

Man Im pissed, I wont say what company I got my rebuilt long block, but its crap. 2000$ pice of it :facepalm: I will never ever order from them again! PM for Details - Still would like to keep my warranty - And NO im not going to contact the company because if this is their product, you can imagine the customer service and I wouldn't trust them with a weed eater!

Ill do it myself then, I know its done correct.

problems:

1. head bolts not sealed - removed and replaced with new and sealed and proper torque used per the manual. Found that at about 15 Mins on the stand - Milkshake valve in and under the valve covers!

2. automotive head gasket were used, I replaced with felpro marine gaskets.

3. drilled and tapped all accessories threads on port head - completely rotten - wouldn't hold 10lbs of torque! 6 x helicoiled

4. just went to re-torque exhaust manifold ( haven't since i put it back together) - pulled the threads out of the Port Head! Was at proper torque when I first installed - UGHHH! Same port head! Just drilled for helicoil but I need

.750 inch only have .50 - so have to wait and order or try to find them local - all auto parts stores that I have found only carry the .50, I need 3/8 x 16 x .750, guess ill get them on FleaBay. I guess I didnt think to look at them while I was doing it!

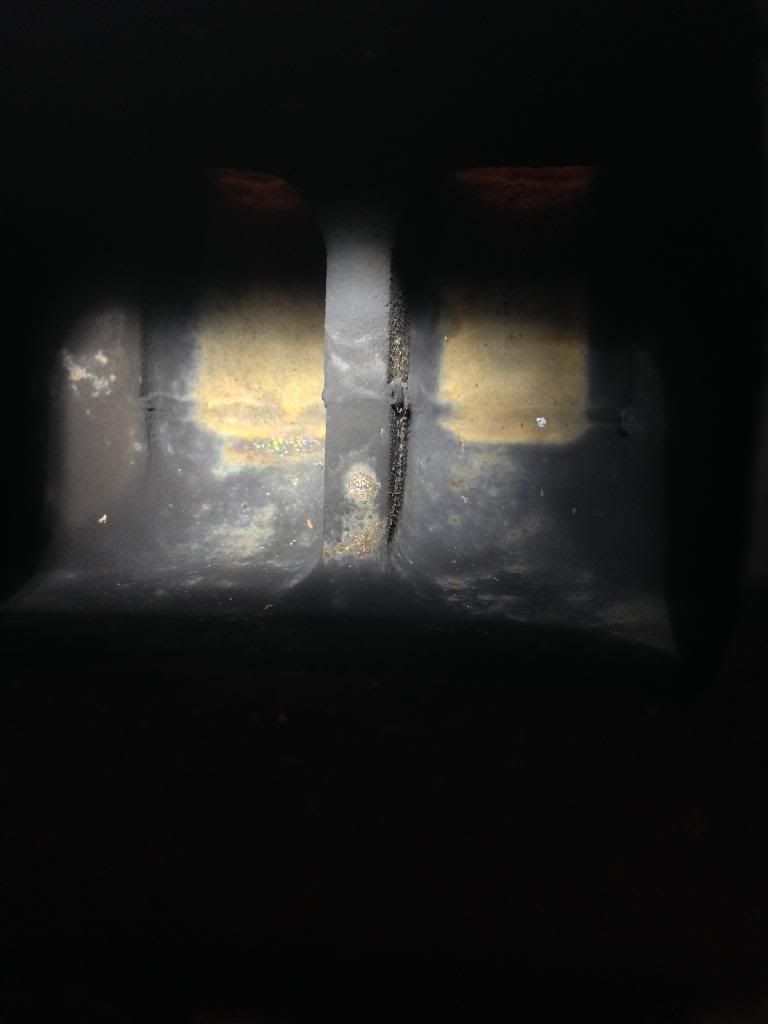

5. When pulling the exhaust manifolds I found water INSIDE! Port and Starboards! When First Installed I checked both manifolds with Acetone didn't find a leak. I cleaned them up well and used new gaskets to install them with. Used the graphite coated ones - shiny, I believe thats whats on em. Was installed in accordance with the Technical Bulletin issued for them.

Just Removed and thats what I found.

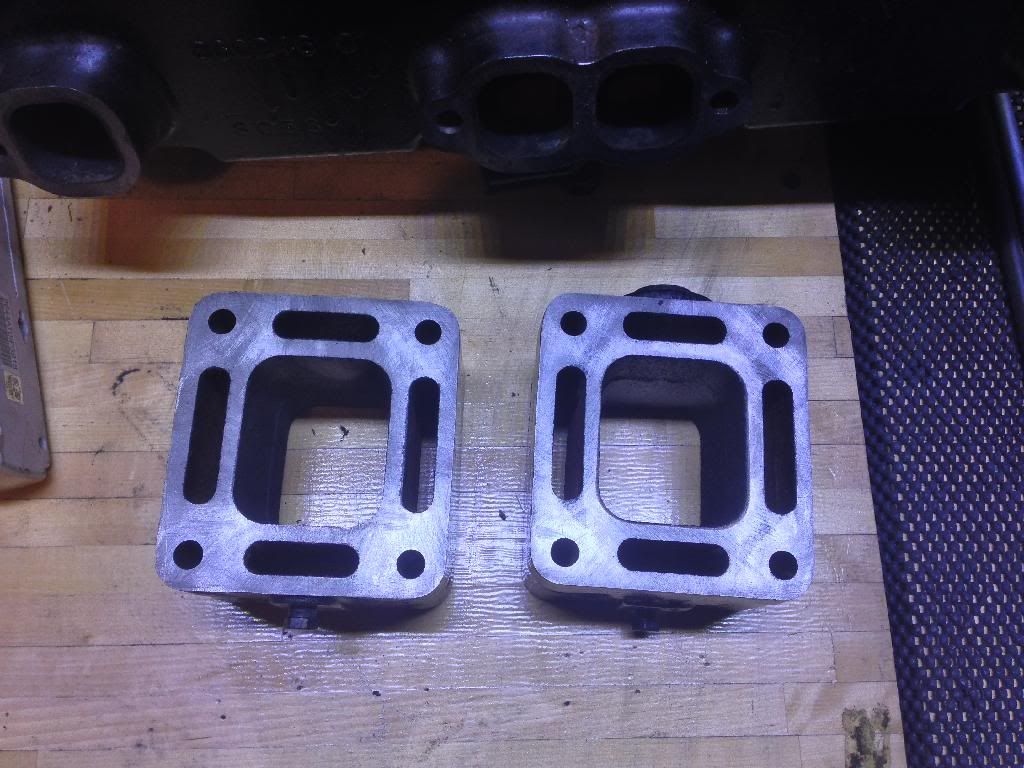

Here is my setup on my Manifolds

{ill post when website will allow - Wont post}

These manifolds came from a freeze busted block, tested them seemed to be ok, now im thinking maybe in the elbows? Any suggestions? Don't want to replace unless I can verify where the leak is coming from - the engine only had 97 hours on it when replaced - freshwater and clean, except for maybe the crack in them - lol - CRAP

Ok now that was my two (or more) Steps back, Here is my one step foward. Was having flex with the alternator bracked assy for the MANDO style brackets. Supposedly there was a recall until 2004 because of misalignment and flexing caused by the old design brackets.

So of course that's what I have - So I FIXED IT

Added flat plate steel to the previously open bracket design.

Added a brace to the rear to stop the torsion and flexing.

Braced the lower bracket and cut out enough for my raw water hose to heat exchanger

This thing is now a TANK - Can definitely say it will not flex any longer!

So now just need to kick my Engine Builders butt and figure out how to pressure test my manifolds-spacers-elbows. I do not want to purchase new ones.

Questions:

Do I loose anything by using a helicoil - meaning tension strength? Seriously all of my port head exaughst manifolds threads looks like paper. I want to replace all eight. Should that be ok?

BTW, yes im using a Torque wrench

Whats your thoughts on my leaking manifolds?

Anyone have a block off plate I could borrow? LOL