Hoosmatroos

Petty Officer 1st Class

- Joined

- Jul 11, 2011

- Messages

- 250

Hello Guys,

Bravo one:

I've just rebuild both my trim cylinders, and replaced all the seals and O-rings, easy job, will open a separate "how to" topic with pictures soon. I dropped the floating piston in the cylinder and pushed it in a couple of inches. Then pushed in the rod. Mounted everything, so far so good. But I'm not sure if it matters that I pushed in the floating piston first. The other cylinder I've pushed the floating piston in with the rod. Off course I have to bleed the system (manuals are all present) but does that position the rod and piston the correct way on both?

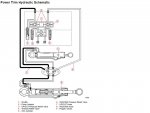

Can anybody explain how this internal works with the check balls and floating piston?

And last, can't find the max trim distance for the Bravo One. Thought it was 21-3/4 inch?

Bravo one:

I've just rebuild both my trim cylinders, and replaced all the seals and O-rings, easy job, will open a separate "how to" topic with pictures soon. I dropped the floating piston in the cylinder and pushed it in a couple of inches. Then pushed in the rod. Mounted everything, so far so good. But I'm not sure if it matters that I pushed in the floating piston first. The other cylinder I've pushed the floating piston in with the rod. Off course I have to bleed the system (manuals are all present) but does that position the rod and piston the correct way on both?

Can anybody explain how this internal works with the check balls and floating piston?

And last, can't find the max trim distance for the Bravo One. Thought it was 21-3/4 inch?