robinsbd

Petty Officer 2nd Class

- Joined

- Dec 7, 2013

- Messages

- 138

Hello,

I am working on the fuel line that goes from the pump to my carburetor. What it is the factory fuel line made of? Is it stainless steel?

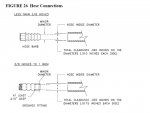

One of the threaded fittings on my line has damaged threads and I'm trying to decide between two options:

1. Replace the fitting and re-flare the existing line.

or

2. Replace the line with a brake line from an auto parts store. The brake line I see at my local store is Poly-Armour steel brake line that is PVF-coated low carbon steel double-wall brake line. These lines already have the inverted flares and fittings. They just need to be shaped.

Is it OK to use the steel brake lines, and if so do you think these will be bad as far as corrosion and longevity?

Right now, I'm leaning towards salvaging my existing line because I'm not sure about the durability of the brake lines. What do you think?

Thanks!

I am working on the fuel line that goes from the pump to my carburetor. What it is the factory fuel line made of? Is it stainless steel?

One of the threaded fittings on my line has damaged threads and I'm trying to decide between two options:

1. Replace the fitting and re-flare the existing line.

or

2. Replace the line with a brake line from an auto parts store. The brake line I see at my local store is Poly-Armour steel brake line that is PVF-coated low carbon steel double-wall brake line. These lines already have the inverted flares and fittings. They just need to be shaped.

Is it OK to use the steel brake lines, and if so do you think these will be bad as far as corrosion and longevity?

Right now, I'm leaning towards salvaging my existing line because I'm not sure about the durability of the brake lines. What do you think?

Thanks!