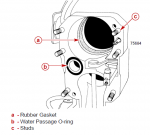

I did a gimbal bearing and bellows recently on a 96 Alpha One gen 2. First time wrenching on something without 4 wheels. Installing the drive with a new paper gasket and round rubber seal in the bellhousing. I got the drive installed, shift shaft and lever aligned but there was a small gap between the drive and the bell before the nuts were run down. I couldn't seat it any further by hand. Maybe a 1/16 of an inch.

I'm assuming this is the new round rubber seal that is waiting to be compressed (between the U-joing bellows internal lock ring and the front of the drive shaft housing extension) by torquing down the 6 drive nuts.

amigright?

I'm assuming this is the new round rubber seal that is waiting to be compressed (between the U-joing bellows internal lock ring and the front of the drive shaft housing extension) by torquing down the 6 drive nuts.

amigright?