mr300z87

Senior Chief Petty Officer

- Joined

- Sep 15, 2010

- Messages

- 694

Hi all, Now that boating season in NJ is coming to a close and my running boat will be coming out of the water soon, I am turning my attention to project Sea Ray. See signature file for link.

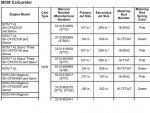

Last night I started to dis assemble for rebuild the Mercruiser Weber carburetor I plan to use which is model 9772 and according to the Merc manual is for a 7.4L Bravo. Inside I found the metering rods to be 16-6852, pink metering rod springs, .101 P .098 S jets on throttle side and .113 P and .077 S jets on choke side, this is all how it should be per Merc Manual 15 V8 engines. My question is that in Merc Manual 16 (Big Block V8s only) it states .107 P and .098 S jets in both sides of the carb and there is a note that some carbs have staggered jets and they should be changes to .107 P and .098 S. The engine I am using is a late 1996 Gen VI 7.4, so during my carb rebuild do I change jets per Manual 16 or leave it as is? As always any advise is greatly appreciated.

Have a Great Day

Mike

Last night I started to dis assemble for rebuild the Mercruiser Weber carburetor I plan to use which is model 9772 and according to the Merc manual is for a 7.4L Bravo. Inside I found the metering rods to be 16-6852, pink metering rod springs, .101 P .098 S jets on throttle side and .113 P and .077 S jets on choke side, this is all how it should be per Merc Manual 15 V8 engines. My question is that in Merc Manual 16 (Big Block V8s only) it states .107 P and .098 S jets in both sides of the carb and there is a note that some carbs have staggered jets and they should be changes to .107 P and .098 S. The engine I am using is a late 1996 Gen VI 7.4, so during my carb rebuild do I change jets per Manual 16 or leave it as is? As always any advise is greatly appreciated.

Have a Great Day

Mike