Bullie

Petty Officer 1st Class

- Joined

- Dec 20, 2014

- Messages

- 300

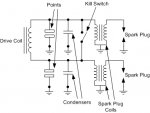

My nephew asked me to see if I could get his Johnson 15 hp model 15R76A running. He said it doesn't have spark, and he was right. I tested at 7/16 and moved in to 1/8 and never got any spark. There is some surface corrosion on the coils. I have not pulled the flywheel off yet. What should be my first move?

I bought a new compression gauge and apparently it sticks at 60 lbs. I tested 3 motors, one I know has 125 lbs compression, and they all maxed out at around 60 lbs. So, I am not certain of the compression as of yet. But, the Johnson showed more compression than my known compression engine (125 lbs) on the gauge. If that means anything. I will take the gauge back and get another asap.

I know this isn't the right forum for this question but maybe you guys can help me out with another motor. I picked up a 9.9 Chrysler Sea King this weekend. It doesn't have any spark either and it will not shift into reverse. I pulled the LU off and could only push the linkage rod down far enough to engage reverse once. After pulling the rod back up into neutral and forward it could not get it to go back into reverse. LU oil looks good. Impeller is good. Any advice you guys can give me on this one is appreciated too.

I bought a new compression gauge and apparently it sticks at 60 lbs. I tested 3 motors, one I know has 125 lbs compression, and they all maxed out at around 60 lbs. So, I am not certain of the compression as of yet. But, the Johnson showed more compression than my known compression engine (125 lbs) on the gauge. If that means anything. I will take the gauge back and get another asap.

I know this isn't the right forum for this question but maybe you guys can help me out with another motor. I picked up a 9.9 Chrysler Sea King this weekend. It doesn't have any spark either and it will not shift into reverse. I pulled the LU off and could only push the linkage rod down far enough to engage reverse once. After pulling the rod back up into neutral and forward it could not get it to go back into reverse. LU oil looks good. Impeller is good. Any advice you guys can give me on this one is appreciated too.