MattinTally

Seaman

- Joined

- Dec 6, 2009

- Messages

- 58

OK, I just wanted to post this after fighting for nearly 3 hours to get the shif shaft linkage reconnected..... Hopefully this can save others down the road. I removed the lower unit to replace a water pump and ran into problems reconnecting the shift shaft. When removing the lower unit, it is important to NOT move the shift rod.... you don't want to unscrew the rod or twist the rod. It should remain exactly as it is when it was disconnected from the powerhead.

To remove the lower unit, the shifter must be in Forward, pushed all the way forward to Full Throttle. To get the lower unit disconnected, I had to have a friend move the shifter on the helm back & forth to relive tension; once the friend did this, the lower unit dropped right out.

To reconnect the lower unit & shift shaft, the shifter must remain fully forward.

First, have a decent repair manual handy. Make sure to have the spark plug wires disconnected and isolated during this procedure. After reading the manual, you'll soon find out there are poor pictures and vague directions regarding reconnecting the linkage and testing.

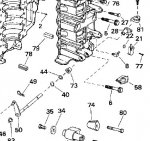

Second, if you run into problems, I would remove the lower cowling pan on the starboard side of the engine. There are 4 bolts; 2 front and 2 aft. The port side cowling can remain in place, but unbolt and move the starboard out of the way. This allows you much better visual access to see where the shift shaft connects into the linkage. NO NEED TO REMOVE ANY OF THE CARBS.

My issue today was when I reconnected and bolted the lower unit back onto the midsection, I must have knocked the shift shaft downward (deeper) into the lower unit and it was then too short at the top end of the shaft to align with the linkage. After rebolting the lower unit, I had to use a pair of long needlenose pliers to grip the shift shaft (down low - you can grip the shift shaft near where the lower unit meets the bottom of the midsection) and move the shift shaft upward about 3/4 inch. Also, when reconnecting the lower unit, the shaft turned slightly and the alignment hole at the top of the shaft was not perfectly perpendicular to the boat (e.g. the hole should be pointing port & starboard and the narrow edge would point fore & aft). I then used the pliers to twist the shift rod to get the alignment hole at the top of the shaft pointing port & starboard.

If the shift rod is in the correct positing (e.g. correct height and hole alignment), the shift shaft linkage (the steel cylinder with the hole for the cotter pin) should easily move into place by hand power and you shouldn't have to use a pry tool, hammer & screwdriver, or anything like that to get the cotter pin installed. If the linkage doesn't easily move into place, you don't have the shift rod height and alignment perfect.

Once you have the linkage arm reconnected and the cotter pin installed, there should be enough room for your fingers to grip the shift shaft up high, just below where the cotter pin is located. If there is any free movement of the shift shaft, you don't have it connected correctly. If correct, there will be virtually no movement in the shift shaft.

Also, at this point, your gear shifter should still be in the fully-Forward position and the prop should only turn clockwise.

Next, have a friend operate the gear shifter while you watch the movement of the linkage and movement of the shift shaft. Watch the shift shaft; as the linkage turns (the cylinder the cotter pin goes thru), the shift shaft should move downward into Nuetral. The prop should now spin freely in both directions. Then have friend move shifter to Reverse, again you should watch the shift shaft. The shift rod should go downward, deeper into the lowe. Recheck the prop movement, it should now spin only counter-clockwise.

If all of this checks out, you have the shift rod reconnected correctly.

Hopefully this will help someone avoid 3 hours of frustration.

To remove the lower unit, the shifter must be in Forward, pushed all the way forward to Full Throttle. To get the lower unit disconnected, I had to have a friend move the shifter on the helm back & forth to relive tension; once the friend did this, the lower unit dropped right out.

To reconnect the lower unit & shift shaft, the shifter must remain fully forward.

First, have a decent repair manual handy. Make sure to have the spark plug wires disconnected and isolated during this procedure. After reading the manual, you'll soon find out there are poor pictures and vague directions regarding reconnecting the linkage and testing.

Second, if you run into problems, I would remove the lower cowling pan on the starboard side of the engine. There are 4 bolts; 2 front and 2 aft. The port side cowling can remain in place, but unbolt and move the starboard out of the way. This allows you much better visual access to see where the shift shaft connects into the linkage. NO NEED TO REMOVE ANY OF THE CARBS.

My issue today was when I reconnected and bolted the lower unit back onto the midsection, I must have knocked the shift shaft downward (deeper) into the lower unit and it was then too short at the top end of the shaft to align with the linkage. After rebolting the lower unit, I had to use a pair of long needlenose pliers to grip the shift shaft (down low - you can grip the shift shaft near where the lower unit meets the bottom of the midsection) and move the shift shaft upward about 3/4 inch. Also, when reconnecting the lower unit, the shaft turned slightly and the alignment hole at the top of the shaft was not perfectly perpendicular to the boat (e.g. the hole should be pointing port & starboard and the narrow edge would point fore & aft). I then used the pliers to twist the shift rod to get the alignment hole at the top of the shaft pointing port & starboard.

If the shift rod is in the correct positing (e.g. correct height and hole alignment), the shift shaft linkage (the steel cylinder with the hole for the cotter pin) should easily move into place by hand power and you shouldn't have to use a pry tool, hammer & screwdriver, or anything like that to get the cotter pin installed. If the linkage doesn't easily move into place, you don't have the shift rod height and alignment perfect.

Once you have the linkage arm reconnected and the cotter pin installed, there should be enough room for your fingers to grip the shift shaft up high, just below where the cotter pin is located. If there is any free movement of the shift shaft, you don't have it connected correctly. If correct, there will be virtually no movement in the shift shaft.

Also, at this point, your gear shifter should still be in the fully-Forward position and the prop should only turn clockwise.

Next, have a friend operate the gear shifter while you watch the movement of the linkage and movement of the shift shaft. Watch the shift shaft; as the linkage turns (the cylinder the cotter pin goes thru), the shift shaft should move downward into Nuetral. The prop should now spin freely in both directions. Then have friend move shifter to Reverse, again you should watch the shift shaft. The shift rod should go downward, deeper into the lowe. Recheck the prop movement, it should now spin only counter-clockwise.

If all of this checks out, you have the shift rod reconnected correctly.

Hopefully this will help someone avoid 3 hours of frustration.