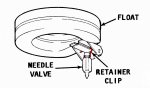

I've set out to do a carburetor cleaning and gasket replacement. I was told that this motor has not run for 30 years and that was backed up by there not being a drop of gas in the carburetor or in any of the old hardened fuel lines attached to it. I really didn't see any build up of anything inside the carb except on the cork float. On the other hand, the gaskets are extremely dried out. And, I've got a few questions about these gaskets:

1. Both inboard needle packing gaskets that seat against metal has become stuck against the carb. The first packing gaskets came out easily. I've been taking a 1/16" drill bit and scraping at the gasket (using it as a scraper, not in a drill), after spraying wd-40 on it, in order to remove it. I just get little bits out, so it's a long process. Anyone have suggestions on how to get these gaskets out?

2. Attached is a photo of the little circular gaskets that came with my rebuild kit. I'm not sure which gaskets go to what. The six in the middle of the photo are the packing gaskets, yes? And I put a skinny gasket on the brass float valve screw and the big gray/brown gasket on the high speed nozzle. Is that correct? Also, the two black rubber circular cross section gaskets and the two metal star washers seem not to apply to my carb. The bigger metal plug is the correct one for my engine.

3. In outboard-boat-motor-repair carb rebuild article, the use of two gaskets against the engine is mentioned. There's only one appropriately sized gasket for my engine in the rebuild kit. I could cut a little larger diameter in the gasket opening in another gasket supplied with the kit if this is really a good idea. Any opinions on that out there?

View attachment 186228View attachment 186228

1. Both inboard needle packing gaskets that seat against metal has become stuck against the carb. The first packing gaskets came out easily. I've been taking a 1/16" drill bit and scraping at the gasket (using it as a scraper, not in a drill), after spraying wd-40 on it, in order to remove it. I just get little bits out, so it's a long process. Anyone have suggestions on how to get these gaskets out?

2. Attached is a photo of the little circular gaskets that came with my rebuild kit. I'm not sure which gaskets go to what. The six in the middle of the photo are the packing gaskets, yes? And I put a skinny gasket on the brass float valve screw and the big gray/brown gasket on the high speed nozzle. Is that correct? Also, the two black rubber circular cross section gaskets and the two metal star washers seem not to apply to my carb. The bigger metal plug is the correct one for my engine.

3. In outboard-boat-motor-repair carb rebuild article, the use of two gaskets against the engine is mentioned. There's only one appropriately sized gasket for my engine in the rebuild kit. I could cut a little larger diameter in the gasket opening in another gasket supplied with the kit if this is really a good idea. Any opinions on that out there?

View attachment 186228View attachment 186228