Re: 1972 electric shift

Yes, you can install a toggle switch to handle gear selection but I think a full understanding of how the electrical portion of the shift mechanism works on this motor is important. Here is how I understand it.

First, understand the basic function of the electrical portion of the shift system. The 1972 65hp is set up to default to forward gear. This means that, absent electrical current to either of the solenoids in the LU, the motor remains in forward gear. Obviously, this is a handy feature if you have electrical problems away from the dock or launch but there is another reason for it, which I will get to in a minute. When the shift circuitry is receiving 12V DC power and the shift handle is in the neutral position, the Shift Selector Switch sends current to the Neutral Solenoid only. In the same situation, but with the Shift Handle in Reverse, both the neutral and reverse solenoids receive 12V DC power and the LU is shifted into reverse gear.

Next, we must understand where the shift circuitry gets its 12V power from and the answer is from three places - the Battery, the Rectifier Assembly and the Shift Diode & Lead Assembly. Both the Battery and the Rectifier Assembly provide a 12V DC source to the Ignition Switch, through which it is also supplied to the Shift Selector Switch when the key is in the on position. With the system wired this way, the Neutral Solenoid in the LU is energized by the Battery as soon as the Ignition Switch is turned to the on position with the shift lever also in the neutral position. Once then engine is started, the Shift Selector Switch receives DC power from both the Rectifier Assembly and the Shift Diode & Lead Assembly, which are wired into the Shift Selector Switch in parallel.

So why is the system set up this way? Receiving power from the Battery is important because it shifts the LU into neutral before the motor is started. Once it is running, electrical power is provided by both the Rectifier Assembly and the Shift Diode & Lead Assembly and there is sound logic in receiving DC power from two sources when the motor is in a running condition. After startup, the motor will remain in Neutral, or be able to shift into Reverse, because the Rectifier Assembly will provide the "juice" to energize the solenoids. At the same time, excess DC amperage flows to the battery for charging. Once in forward gear, there is no draw (the other reason why defaulting to Forward is advantageous) from the solenoids, and the DC power is directed towards battery charging and running the accessories in the boat. And, not to forget the Shift Diode & Lead Assembly, with this second source of DC power, the LU will remain in Neutral after the Ignition Switch is turned to the off position, because the spinning Flywheel will generate power to send to the Neutral Solenoid. This prevents a surge forward that would otherwise occur between turning off the Ignition Switch and the point at which the motor has stopped turning.

Now that we understand all of that, I think a few things become clear. First, you can not accidentally shift into two gears at once because the electrical system isn't set up in a way that would allow this. Second, I agree that a diode is needed in the home made setup So, absent the issue of the starter cutout circuitry, all we need to do is to bypass the defective Shift Selector Switch by disconnecting all of the shift wires to it, and rerouting them to our replacement switch.

Here are the wires to be concerned with:

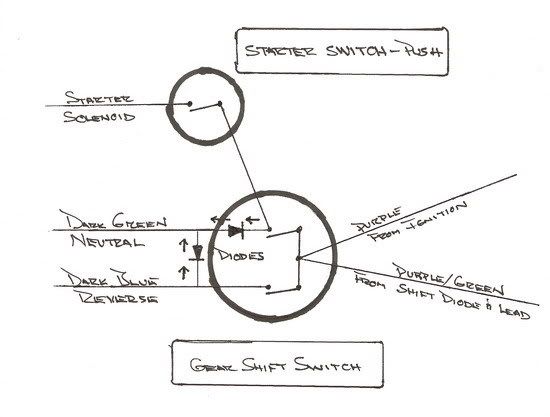

White Wires - these are for the starter cutout circuitry. If luck has it that this portion of the Shift Selector Switch is still working, I would leave the switch in place with these wires intact. May as well let them continue to do their job and be able to use the Start Position on the Ignition Switch. If, however, they don't work, another possibility is to bypass the Start Position on the Ignition Switch and use the switched side of the neutral position on our new shift switch, to feed yet another switch (pushbutton type?). This would energize the Starter Solenoid but it would require the use of another Diode to prevent feedback when Reverse is selected - see diagram.

Purple Wire - this wire supplies 12V DC from the Ignition Switch. It is supplied by the Battery and Rectifier Assembly (red wire to Ignition Switch), via a fused circuit to the battery side of the Starter Solenoid. It is one of the wires that should go to the hot side of the new gear shift switch.

Purple/Green Wire - this wire provides 12V DC from the Shift Diode & Lead Assembly. It is the second wire that should be connected to the hot side of the new gear shift switch.

Dark Green Wire - this is the wire that provides 12V DC to the Neutral Solenoid. It should be connected to both the switched side of the neutral position, and the switched side of the reverse position, on the new gear shift switch. A diode would be needed here to prevent power from feeding back to the Reverse Solenoid when Neutral is selected.

Dark Blue Wire - this is the wire that provides 12V DC to the Reverse Solenoid. It should be connected only to the switched side of the reverse position on the new gear shift switch.

Here's what I would envision in the form of a schematic to accomplish all of this:

So, what are the problems in this installation? The biggest one that I see is the one that Joe Reeves mentioned in his post - extreme caution would need to be taken to prevent unwanted shifts with power on the motor. His idea of a guarded switch would help in that regard. There is one problem with this approach, however, in that use of a guard would make switching the LU to neutral cumbersome. Obviously, this could have some negative consequences when operating near a dock or other boats. I do like Jameskb2's approach because it might eliminate that problem.

All in all, I guess I would make the home made switch if I had to but I would sure get on a hunt via the auction sites, Craigslist, etc. to find a used control unit first. I found one for my boat on EBay some time ago and have kept it to canabalize as needed to keep my unit functioning. I don't remember what I paid for it but I want to say that it was about 80 bucks with shipping.

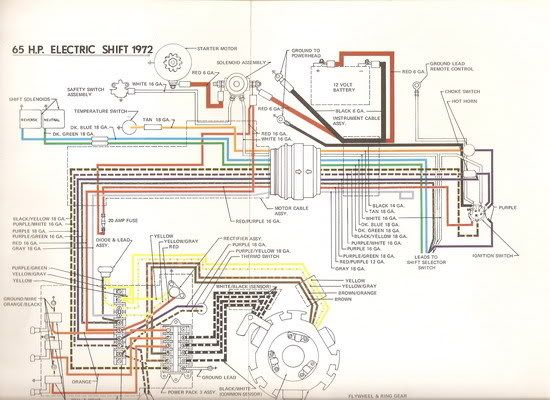

PS: Just in case anyone is interested, here is the OEM wiring schematic for a 1972 Johnson 65hp motor. To make it more legible, save the image to your disk and load it into a photo manipulation program or Windows Picture and Fax Viewer - it can be enlarged in either of these.