AntiqueTbird

Cadet

- Joined

- Jul 1, 2012

- Messages

- 29

Does anyone have actual IRL experience with this on a 4v x-flow?

I spoke on the phone with a big distributor here in Florida that also happens to work on a lot of motors .

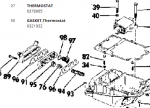

The old timer OMC mechanic said that when ever he got a Central-South Florida x-flow 4v in that was having any major work done on it the first thing he did was take the thermostat housing off and put the outer cover back on without the plastic valvebody, tstats, and poppets. He's worked on hundreds of of v4 x-flows and did this to most of them. The reasoning was that operating the engine in south Florida and central west Florida the water isn't cold enough to need them. The engine will run a touch cold but with proper piston to bore clearance and a warm up on cold starts it will never over heat or cold seize. He said the x-flows were known for running hot on the high (starboard) side and the only thing to do with them was to have all of the thermostat housing open and just let the water flow. He said that if the motor was going to be run up north on a lake with .125" of ice still on top the tstats are needed but down here where the water doesn't go much below 70f they just overheat. He said that if I let the engine idle for 5-10 minutes after start up it will be perfectly fine. If I drop in and just stab it and go for WOT after starting it will probably not be.

I know that Thermostats are at the center of many "heated" debates. I was of the impression that they are absolutely necessary on 2-stroke O/B motors. I can say that in my experience here in south Florida I have gotten into the habit of removing the tstat from my truck during the summer. The engine still gets to operating temp in less than 5 minutes and the A/C works alot better. Winter or a trip up north after about august and I put the tstat back in the truck so the heater works better sooner.

If anyone on here has tried this in the warmer subtropical climates please let me know how it worked out. I'm getting ready to put this thing back together and would like it to work better and last longer between teardowns and avoid completely another piston seizure and have more reasonable temps.

Thanks ya'll.

I spoke on the phone with a big distributor here in Florida that also happens to work on a lot of motors .

The old timer OMC mechanic said that when ever he got a Central-South Florida x-flow 4v in that was having any major work done on it the first thing he did was take the thermostat housing off and put the outer cover back on without the plastic valvebody, tstats, and poppets. He's worked on hundreds of of v4 x-flows and did this to most of them. The reasoning was that operating the engine in south Florida and central west Florida the water isn't cold enough to need them. The engine will run a touch cold but with proper piston to bore clearance and a warm up on cold starts it will never over heat or cold seize. He said the x-flows were known for running hot on the high (starboard) side and the only thing to do with them was to have all of the thermostat housing open and just let the water flow. He said that if the motor was going to be run up north on a lake with .125" of ice still on top the tstats are needed but down here where the water doesn't go much below 70f they just overheat. He said that if I let the engine idle for 5-10 minutes after start up it will be perfectly fine. If I drop in and just stab it and go for WOT after starting it will probably not be.

I know that Thermostats are at the center of many "heated" debates. I was of the impression that they are absolutely necessary on 2-stroke O/B motors. I can say that in my experience here in south Florida I have gotten into the habit of removing the tstat from my truck during the summer. The engine still gets to operating temp in less than 5 minutes and the A/C works alot better. Winter or a trip up north after about august and I put the tstat back in the truck so the heater works better sooner.

If anyone on here has tried this in the warmer subtropical climates please let me know how it worked out. I'm getting ready to put this thing back together and would like it to work better and last longer between teardowns and avoid completely another piston seizure and have more reasonable temps.

Thanks ya'll.