cfauvel

Chief Petty Officer

- Joined

- Aug 16, 2005

- Messages

- 645

Wanted to share some of my findings about the oil side of the VRO2/OMS

I have been plagued with some dripping oil from my VRO and wanted to address it.

Tightening the clamp on the hose at the inlet didn't help so decided to figure out where it was leaking from.....now I know

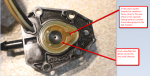

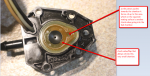

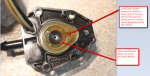

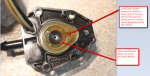

found the leak to most likely be the top o-ring on the pin that used to count the pulses

Cleaned up

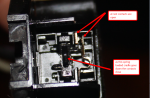

what is going on the opposite side of the oil electronic and chamber

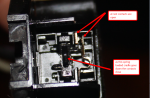

The pin that goes to the electronic side is an activator of a set of tiny contacts.

The o-ring is the pivot point, as oil pushes up on the fuel side, it pushes down at the opposite side and indirectly closes the contacts, which must be registered in the electronics and counted.

Whilst I had the pump off I replaced the o-rings for all the inlets and outlets and inspected the air motor and fuel pump (both were fine).

did some vacuum tests once all back together and tested fine...

will run off of a pre-mixed gallon of fuel, test the NO-oil circuit and test that indeed oil is being drawn in via a clear tube connected to the oil inlet..

When I get the parts back together I'm going to take a video of the counter doing it's thing..

Being a frustrated Mech Engineer I like that they went mechanical to do the counter, rather than some tricky impedance mechanism like I thought it was.

(Correction 07/05/2017- the pin is NOT a counter, rather it is counter RESET, the counting takes place in the electronics based on TACH pulses (not revolutions per minute) )

compare the number of closed contacts to the revolutions per minute and if not in the right range no-oil alarm sounds....initially decades ago I thought the electronics did the pumping, it wasn't until another decade or so when I read that VRO bible on Continuous Wave that the electronics had no bearing on the pumping of oil.

Would love to know the chart between counts of oil cycle to revolution per minute.

(Correction 07/05/2017 - the electronic part counts up to 8192, if it reaches that number before the reset pin resets the counter back to 0 then the alarm sounds)

I have been plagued with some dripping oil from my VRO and wanted to address it.

Tightening the clamp on the hose at the inlet didn't help so decided to figure out where it was leaking from.....now I know

found the leak to most likely be the top o-ring on the pin that used to count the pulses

Cleaned up

what is going on the opposite side of the oil electronic and chamber

The pin that goes to the electronic side is an activator of a set of tiny contacts.

The o-ring is the pivot point, as oil pushes up on the fuel side, it pushes down at the opposite side and indirectly closes the contacts, which must be registered in the electronics and counted.

Whilst I had the pump off I replaced the o-rings for all the inlets and outlets and inspected the air motor and fuel pump (both were fine).

did some vacuum tests once all back together and tested fine...

will run off of a pre-mixed gallon of fuel, test the NO-oil circuit and test that indeed oil is being drawn in via a clear tube connected to the oil inlet..

When I get the parts back together I'm going to take a video of the counter doing it's thing..

Being a frustrated Mech Engineer I like that they went mechanical to do the counter, rather than some tricky impedance mechanism like I thought it was.

(Correction 07/05/2017- the pin is NOT a counter, rather it is counter RESET, the counting takes place in the electronics based on TACH pulses (not revolutions per minute) )

compare the number of closed contacts to the revolutions per minute and if not in the right range no-oil alarm sounds....initially decades ago I thought the electronics did the pumping, it wasn't until another decade or so when I read that VRO bible on Continuous Wave that the electronics had no bearing on the pumping of oil.

Would love to know the chart between counts of oil cycle to revolution per minute.

(Correction 07/05/2017 - the electronic part counts up to 8192, if it reaches that number before the reset pin resets the counter back to 0 then the alarm sounds)

Attachments

Last edited: