I have a 1981 Johnson 140. The lower unit was full of rust and the water pump was bad, and I hadn't figured out which prop combination I need yet for the boat I put it on. So I grabbed the lower unit that was running perfectly on my 110 Evinrude (1989) @ 5200 RPM on plane. On this 140 Johnson I'm only getting 4200 RPM and 31 mph. Same lower unit and prop runs 1,000 rpm higher and 10 mph faster on the 110 evinrude (same boat). It takes a while to get on plane, pretty weak actually. All coils are new, all cylinders are firing. Timing is set at 28 full. Compressions are now 125-135.

The plugs are coming out a little black, but never fouled. I'm also running the surface gap plugs if that makes a difference. I've gone through the carbs and set the floats, cleaned all the jets and ports thoroughly. It's a quiet and very smooth running engine, the smoothest one I've had yet, but NO POWER.

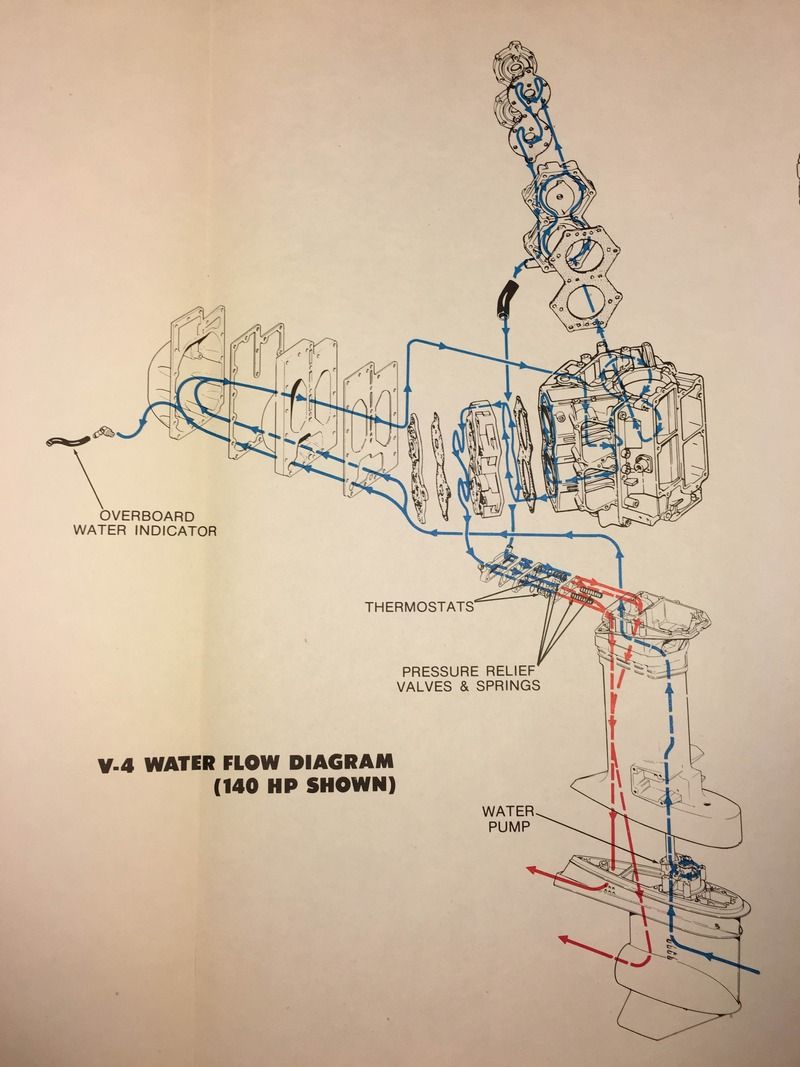

I'm trying to figure out if there's any possibility of an exhaust problem that could be creating too much back pressure. In the past I've had 2 strokes that run perfectly except at full power, and it was because of an internal water leak into the exhaust, creating a massive amount of back pressure. Incedently on pretty much all the outboards I've had, they pour a lot of water out the prop/exhaust when running to flush the engine. This engine doesn't have one droplet of water coming out the exhaust....maybe there's supposed to be some water and it's not getting there? The upper round exhaust ports are dry too, and barely have any air puffing out of them. The thermostats are also new btw.

The reeds are all intact, but I didn't pull the intake to check for reed stuffers. My 110 had the rubber blocks in there ( I added them) and had performance reeds. I also had high compression 140 heads on the 110, but not sure if that ever actually made a real difference. I don't think I need the high compression heads to get another 1,000 rpm. There's no way I need a different prop if a 110 was making that much more power than this 140 is with the same prop and lower unit. (it's a Looper lower unit originally but had it all figured out with the correct prop on the 110, was running perfect until the block cracked at on of the head bolts.

Is there a gasket under the intake that is supposed to separate the airflow, that could be causing low full power? Also, what jets should I have, maybe someone put the wrong ones in there. It has 1 5/16 carbs. One other thought is that what if it was somehow siphoning fuel from the primer lines into the cylinder, from a weak sealed line somewhere- is that common?

Whatever the problem is, it runs great except full power is just weak.

The plugs are coming out a little black, but never fouled. I'm also running the surface gap plugs if that makes a difference. I've gone through the carbs and set the floats, cleaned all the jets and ports thoroughly. It's a quiet and very smooth running engine, the smoothest one I've had yet, but NO POWER.

I'm trying to figure out if there's any possibility of an exhaust problem that could be creating too much back pressure. In the past I've had 2 strokes that run perfectly except at full power, and it was because of an internal water leak into the exhaust, creating a massive amount of back pressure. Incedently on pretty much all the outboards I've had, they pour a lot of water out the prop/exhaust when running to flush the engine. This engine doesn't have one droplet of water coming out the exhaust....maybe there's supposed to be some water and it's not getting there? The upper round exhaust ports are dry too, and barely have any air puffing out of them. The thermostats are also new btw.

The reeds are all intact, but I didn't pull the intake to check for reed stuffers. My 110 had the rubber blocks in there ( I added them) and had performance reeds. I also had high compression 140 heads on the 110, but not sure if that ever actually made a real difference. I don't think I need the high compression heads to get another 1,000 rpm. There's no way I need a different prop if a 110 was making that much more power than this 140 is with the same prop and lower unit. (it's a Looper lower unit originally but had it all figured out with the correct prop on the 110, was running perfect until the block cracked at on of the head bolts.

Is there a gasket under the intake that is supposed to separate the airflow, that could be causing low full power? Also, what jets should I have, maybe someone put the wrong ones in there. It has 1 5/16 carbs. One other thought is that what if it was somehow siphoning fuel from the primer lines into the cylinder, from a weak sealed line somewhere- is that common?

Whatever the problem is, it runs great except full power is just weak.