My needles are to spec, meaning the low-speed is about a turn, to a turn and a half. The high speed is about one turn out. I think, within a fraction of a turn, each motor is slightly different than the other. I understand what your saying about the packing nut, not being snug/tight, as I experienced the same thing. After all the carb tear-downs, I forgot the snug down the high-speed and.... yeah, my "

frustratedboater" in me surfaced! No

pun intended...

I had set my low speed needle 1-1/2 and ran it and I would fine tune it just to clear the blue smoke but out enough past the coughing of the motor when fuel was starved and same with the high...

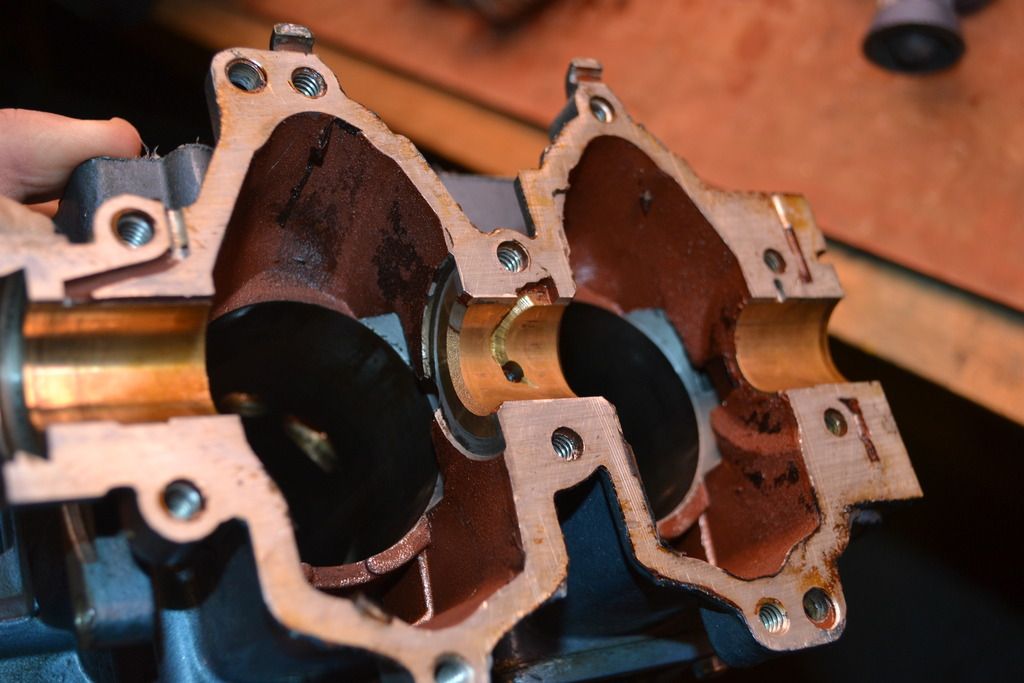

On another note, while I tore the powerhead completely apart, I discovered some interesting things that I never came across before. Check it out:

Look at the rubber pressure reed from the inside view (left one), there is small piece of gasket sealer between the seating of the damper, thus, perhaps, not providing me the pressure I need for the tank/or motor? Do you see it sitting there?

The other side of the damper: (do you see it on the left? That little piece sticking out?

Also all the extra gasket sealer all throughout the mid-block section:

I'm sure there are other minor issues all contributing to this, but the sun shone a little brighter for me this morning when I saw that!

I didn't take a picture of the pistons, but they looked really good with no visible signs of butter wear. but the rings did look tired. I will seat them in their cylinder and take a measurement just to see. Also, after the complete tear down, my cork gasket directly under the crank, wasn't seated properly and was slightly hung up on the base gasket, so I'm glad to have caught that! One real bummer, is that I noticed a milky drip from the lower unit.... yup! (

after I just replaced all the seals and spaghetti seal...... GRRRRR!).

Work to be done..., Ohh but it is GOOD work!