sutor623

Rear Admiral

- Joined

- May 23, 2011

- Messages

- 4,087

Hey guys, most of yall know I have been having issues with my'95 130hp. Finally figured out why the head wasnt reaching operating temp and fixed that. (water blockage on port side head.)

I have been wondering why the motor fails cylinder #1 and #3 drop test at idle. I suspected a past overheat because the thermostat housing was melted through when I changed it. I was thinking that I had a blown head gasket from the overheat. But this all puzzled me because compression in the motor is 130 across the board, and a leakdown test yielded under 10% loss on all cylinders.

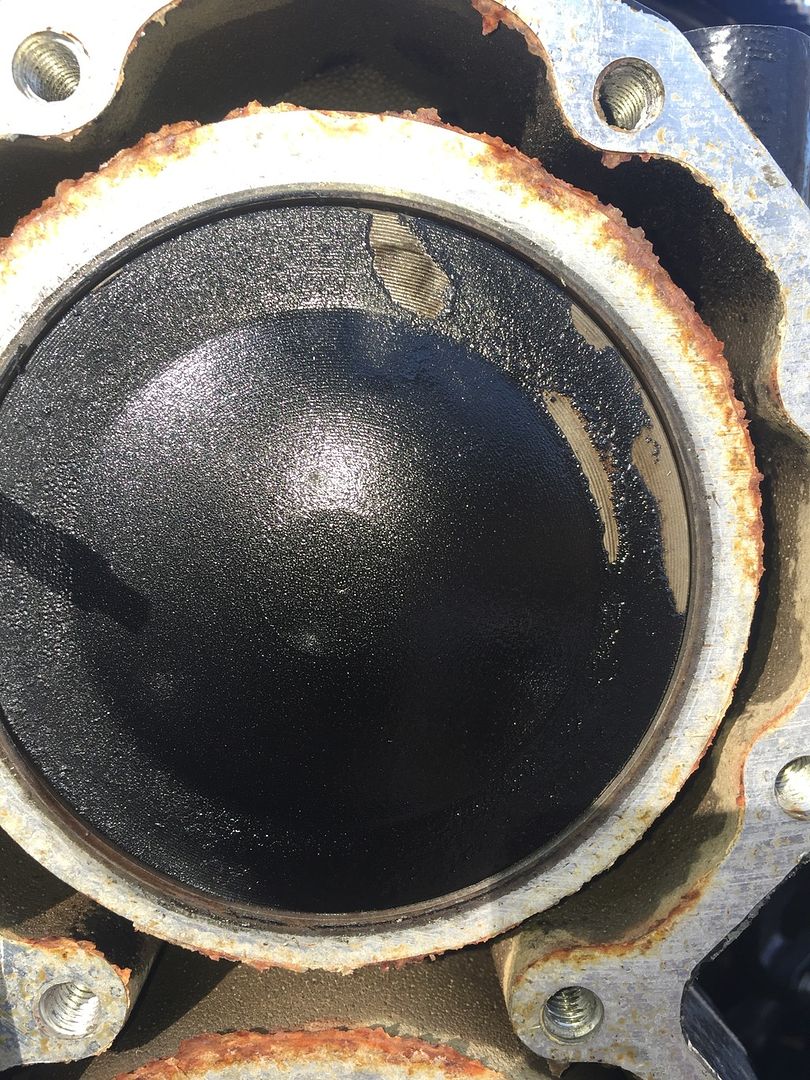

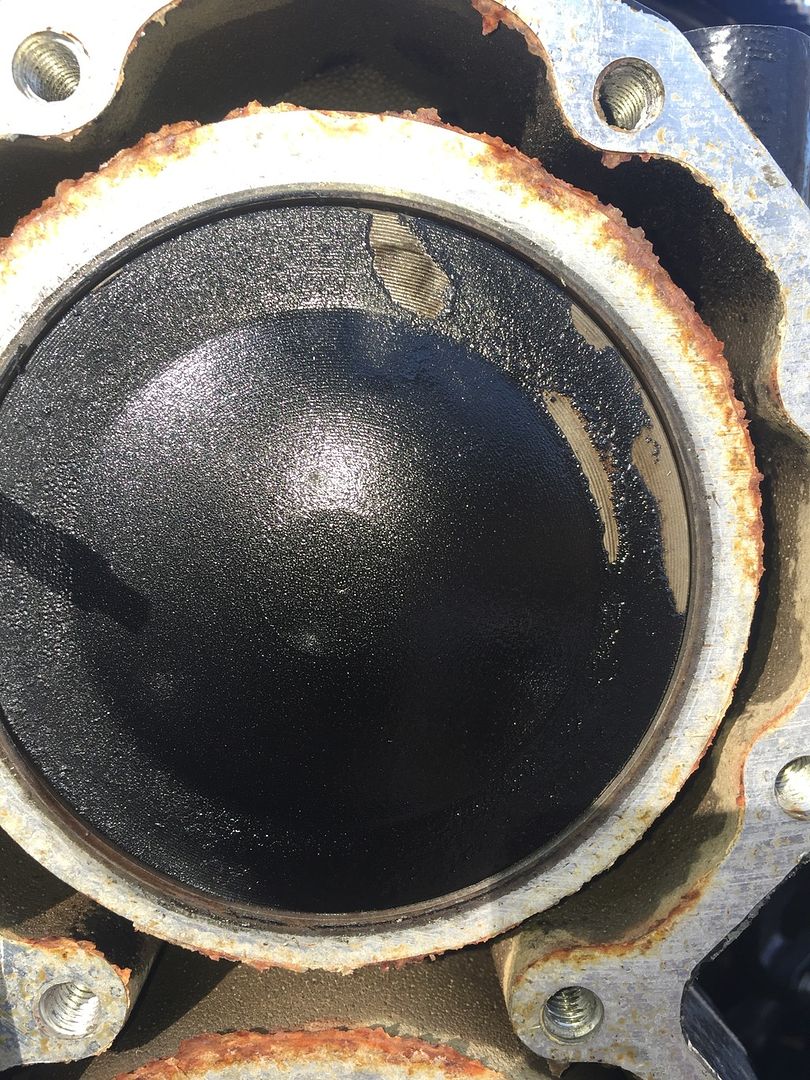

Does this look like water entry to you? It sure does to me. Looks like 1 is gettin it real good, and 3 is getting some also.

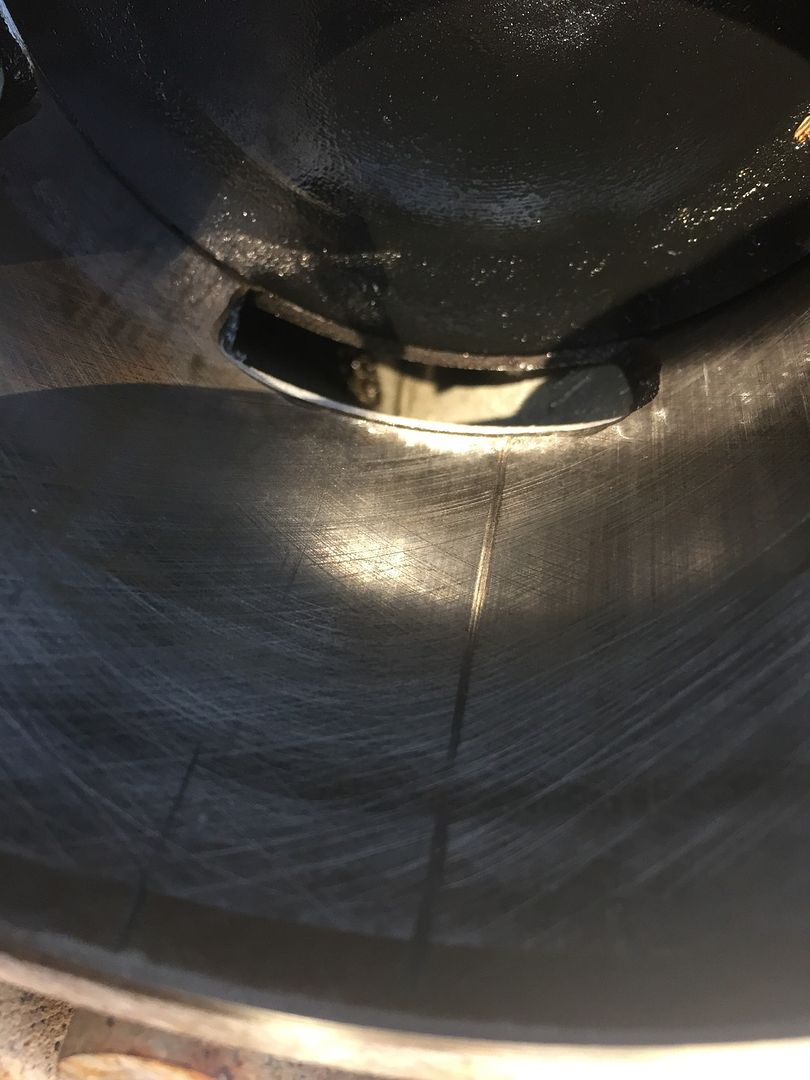

On another note, I have some scoring on #1 cylinder. It doesnt even look like it is through the hone in most spots. You cant feel it with your fingernail in most spots. But you can in two spots, ever so slightly.

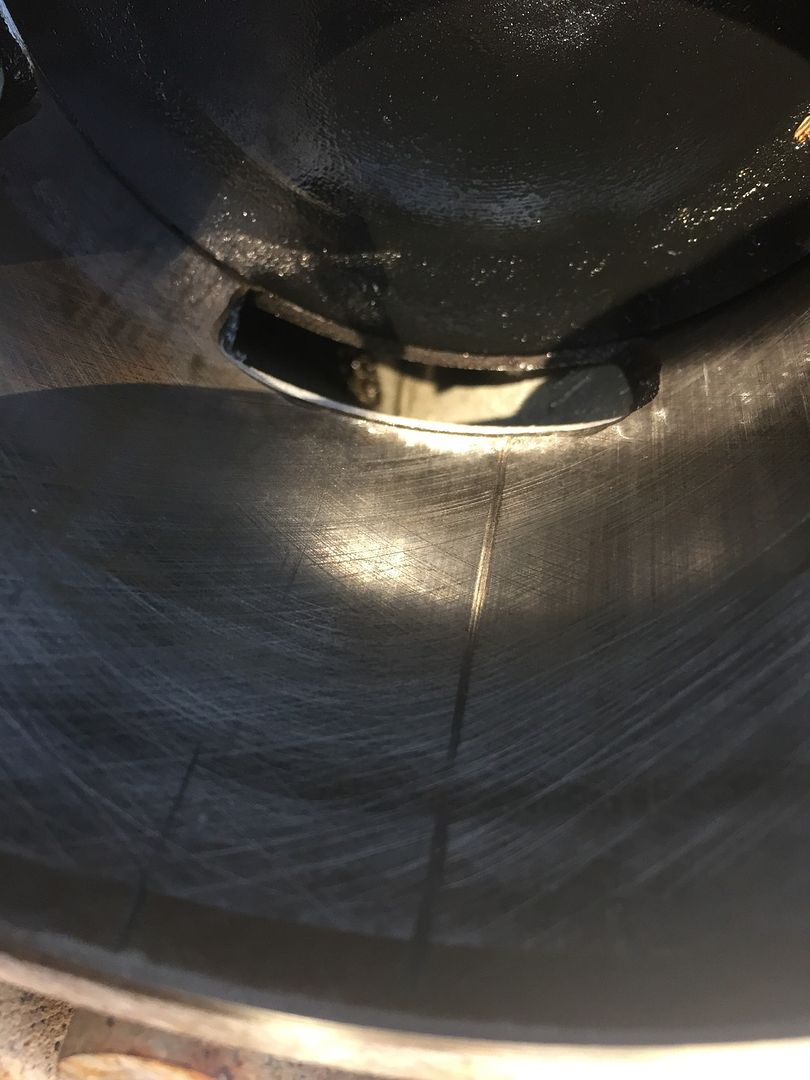

Here is cyl#3. It also fails the drop test, but not as much as 1. Very light scoring.

I have a new headgasket setting right in front of me. The motor has plenty of power to get on plane, mid range and full throttle. Only issue is hard starting and long warm up times. (Will NOT start in 30 degree weather unless its on the muffs.) I feel like most of the issues I am dealing with are from water in these two cylinders, but do not have experience on the wear of engines. Would you guys put the new headgasket on and see how it does, or is this a disaster waiting to happen? Remember, the cylinder holds good compression (Not that that is the tell all test.)

I have been wondering why the motor fails cylinder #1 and #3 drop test at idle. I suspected a past overheat because the thermostat housing was melted through when I changed it. I was thinking that I had a blown head gasket from the overheat. But this all puzzled me because compression in the motor is 130 across the board, and a leakdown test yielded under 10% loss on all cylinders.

Does this look like water entry to you? It sure does to me. Looks like 1 is gettin it real good, and 3 is getting some also.

On another note, I have some scoring on #1 cylinder. It doesnt even look like it is through the hone in most spots. You cant feel it with your fingernail in most spots. But you can in two spots, ever so slightly.

Here is cyl#3. It also fails the drop test, but not as much as 1. Very light scoring.

I have a new headgasket setting right in front of me. The motor has plenty of power to get on plane, mid range and full throttle. Only issue is hard starting and long warm up times. (Will NOT start in 30 degree weather unless its on the muffs.) I feel like most of the issues I am dealing with are from water in these two cylinders, but do not have experience on the wear of engines. Would you guys put the new headgasket on and see how it does, or is this a disaster waiting to happen? Remember, the cylinder holds good compression (Not that that is the tell all test.)

Last edited: