That sort of spark test is useless really.

You need to invest in an open air gap spark tester. One you can adjust. For the OMC magneto ignition, set it to 1/4"

The reason is this. Many motors will show spark when tested like you did, but will not run, and it fools you into thinking you have a fuel delivery issue. The spark has to be able to jump the gap, under the compression in the cylinder, which you don't have when you test in open air like that. So, adding the 1/4" gap on the adjustable tester, helps mimick the compression in the cylinder, and makes it harder for the spark to jump. Real laymans type explanation, but you get the idea.

These testers are like 5 bucks, and a must have.

The primary windings in the coil, are short, and fat, and almost always good. The secondarys are long and thin, and often the problem with a failed coil. If the coil is cracked, and original, chuck it, no matter if it passes a continuity test or not.

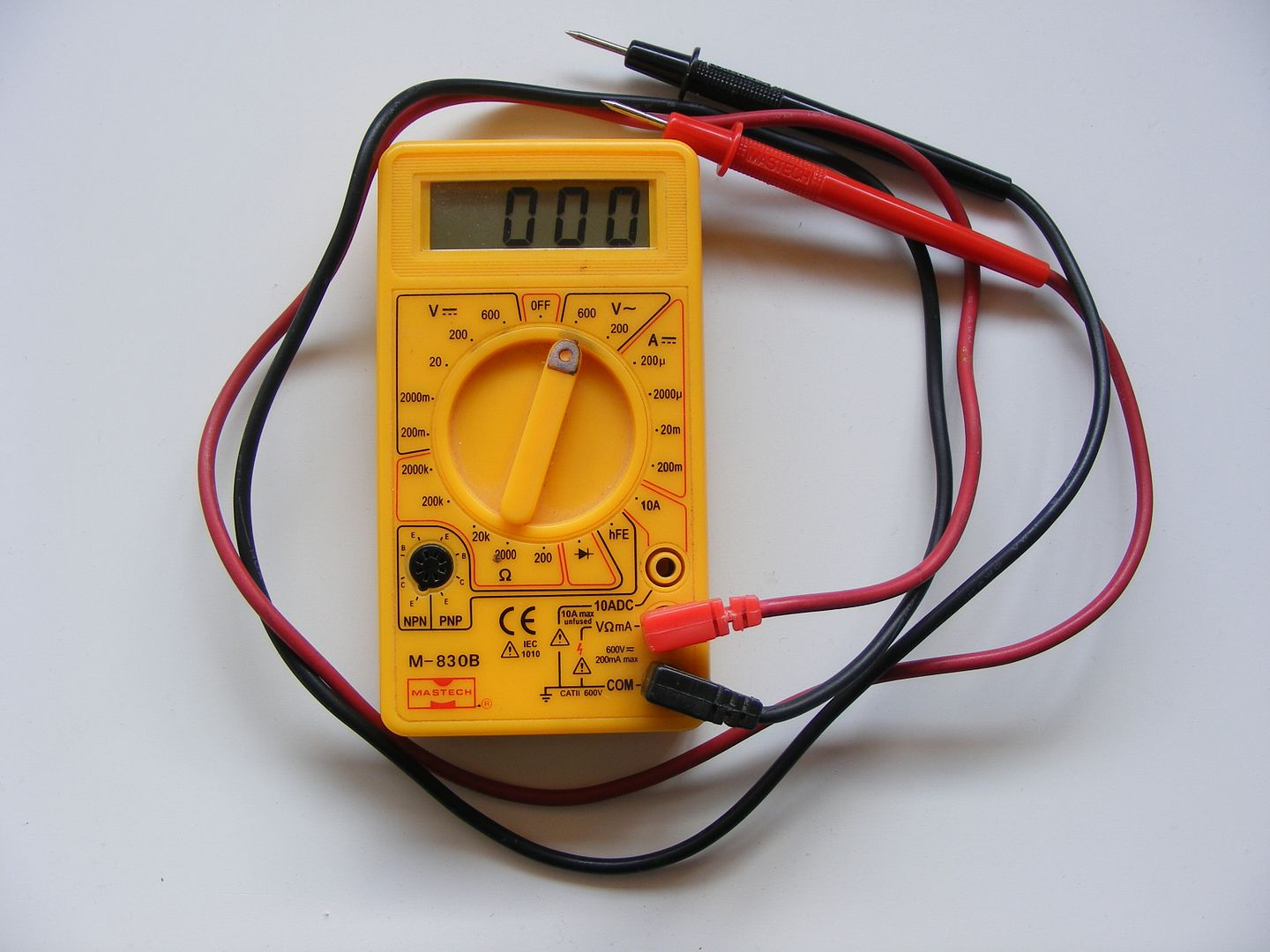

Some coils will pass a continuity test of the primary and secondary with a standard multi meter, but still not work. That is where testing equipment like a Mercotronic comes in. It puts a load on the coil to test. Sometimes, the secondary is cracked, or severed, but just slightly touching. It will show continuity, and you think its ok. Then on the water, it will fail when it heats up, and the fractured wires separate, losing continuity. You go home and test it again, once cooled, and it tests fine. You get the idea there where you need the right equipment.

If the condensors are the red paper tops, they are original, and should be changed, especially if you don't have the ability to test them. If they have black rubber caps, they have likely been changed, and may be ok. I almost never change points, I like the originals quality better than what you get nowadays, unless the rubbing blocks are so worn you must. Simply polish them, by either a points file, or touch them against a wire wheel on a bench grinder, then set clean with brake cleaner and install. Set to 020, then dip business card or paper stock in acetone, and run that through to clean again. Your fingerprints will limit spark. Now blow off with compressed air and you are done.

When you install the wires into the coils, pull through excess wire from under mag plate, and twist the coil onto the wire. Then push back down and secure to bottom of plate.