JerryB1987

Seaman

- Joined

- Apr 19, 2015

- Messages

- 62

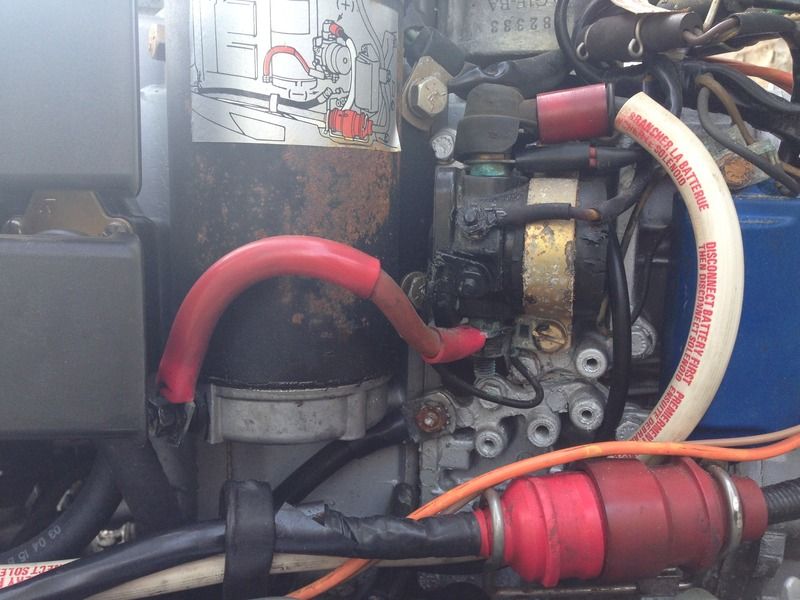

I have a boat that was given to me that has a 90 HP Johnson outboard. When I got it all the wires were disconnected and there was no battery. I found in the engine where the diagram shows to hook the positive lead but there is no indication or drawing in the manual I bought that shows the best place to hook the ground connection. Anyone have a picture where the best place to attach the ground would be? It was just laying in the splash well along with the positive so I don't know where it should be hooked to that will provide a good ground