Sorry folk, it's not a dirty carb issue, the hidden screw only adjusts the air/fuel mixture idle speed setting, has nothing to do while OB runs at higher revs past idle rpm as the jets are fixed, non adjustable ones whatsoever.

There's a huge carb/timing advance desynchronization. The 8 comes factory adjusted for timing plate and matting surface to stop at 22? at full throttle and 1.5? at mim throttle while the 9.8 comes factory adjusted to stop at 26? and 2.5? respectively.

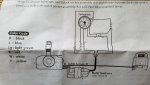

What you can do to end your boating frustration is remove cowl, stand at middle powerhead, crouch a little to have timing marks at sight level, with OB -Off full throttle, check at which timing mark does plate stops at. Large stamped mark is 0?, smaller ones past 0? are + 5?, before 0? is minus? territory.

Check which bolt, nut whatever restricts timing plate to travel forward, undo it till timing plate stops at 26?, adjust when there, secondly, need to synch carb to fully open butterfly when timing synch has stopped at 26?, check whatever restrics its movement.In some Tohatsu OB's moving timing advance will advance the carb synch accordingly, check if moves same.

Just in case, before moving anything take pics of the original time advance /carb synch. Can't help any further as don't have at hand nor use a 9.8 horse to the displeasure of some. Probably Paul can add more information about the timing procedure, what to undone, move, unscrew whatever more precisely. Report your findings...

Happy Boating