masonman

Cadet

- Joined

- Aug 11, 2017

- Messages

- 11

I have one of the older force 125 . the problem is a leakdown with the trim up.

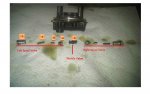

leakdown test shows something wrong with the valve body.

like a dumb *** i took it apart and now dont know how to put back together, balls springs and all.

i suspect now its the check valve thats held in with the 2 snap rings.

i havent took that out or apart yet.

i found a few new valve body assembly but $108.00

http://www.ebay.com/itm/NEW-Force-6...09-/152053568476?_trksid=p2385738.m2548.l4275

I hate to do that if i can get this back together and make it work rite.

i can not find any blown up teardown diagram anywhere on the big www

or in the kinda usless force book .

does anybody have a diagram i can print off.

I sure hope i can get this back together and make it work.

also any advise about the check valve i dident take out yet.

thanks in advance.

force 125 one of the blue purple ones.

leakdown test shows something wrong with the valve body.

like a dumb *** i took it apart and now dont know how to put back together, balls springs and all.

i suspect now its the check valve thats held in with the 2 snap rings.

i havent took that out or apart yet.

i found a few new valve body assembly but $108.00

http://www.ebay.com/itm/NEW-Force-6...09-/152053568476?_trksid=p2385738.m2548.l4275

I hate to do that if i can get this back together and make it work rite.

i can not find any blown up teardown diagram anywhere on the big www

or in the kinda usless force book .

does anybody have a diagram i can print off.

I sure hope i can get this back together and make it work.

also any advise about the check valve i dident take out yet.

thanks in advance.

force 125 one of the blue purple ones.

Last edited: