You're right about the wasted spark ignition. That's only applicable on systems where they fire two cylinders with a single coil. Scratch that idea.

Anyways, check the reeds.

Also double check the fuel enrichment solenoid if you have that instead of a mechanical choke. Sometimes the enrichment valve will stick open and keep dumping fuel into the intake. It should have a black button on the top that you can push to manually open the valve. A couple of pushes and a couple shots of carb cleaner may fix it if it's a problem.

If that all checks out, then take a look at the stator voltages and all wires (stator and trigger) going to the Switch Box.

Anyways, check the reeds.

Also double check the fuel enrichment solenoid if you have that instead of a mechanical choke. Sometimes the enrichment valve will stick open and keep dumping fuel into the intake. It should have a black button on the top that you can push to manually open the valve. A couple of pushes and a couple shots of carb cleaner may fix it if it's a problem.

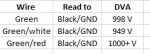

If that all checks out, then take a look at the stator voltages and all wires (stator and trigger) going to the Switch Box.