I replaced my trim valve body due to the old one bleeding down. When I went to raise the motor the switch stayed engaged and the motor continued to run in the full up position for a several seconds until I could stop it. Once stopped I couldn't get the motor to lower via the switch. So I unscrewed a allen plug on the valve body and lowered the motor to full down.

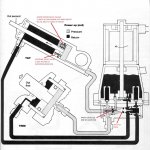

I then installed a brand new tilt motor and switch and still the motor won't raise or lower. I verified the motor is spinning in both directions via the switch. However it seems as if its not pushing any fluid. Also, I try to manually lift up the motor but it will only come up 3-4 inches. It almost seems like its a hydraulic lock. Any way to relieve the pressure. This model doesn't have a manual relief valve.

I then installed a brand new tilt motor and switch and still the motor won't raise or lower. I verified the motor is spinning in both directions via the switch. However it seems as if its not pushing any fluid. Also, I try to manually lift up the motor but it will only come up 3-4 inches. It almost seems like its a hydraulic lock. Any way to relieve the pressure. This model doesn't have a manual relief valve.