tashasdaddy

Honorary Moderator Emeritus

- Joined

- Nov 11, 2005

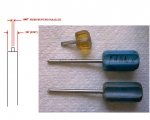

- Messages

- 51,019

these are directions for 2 cylinder, 2 carbed motors, but the principle follows for most other carbs.

Cleaning Carburetors First i ask you to follow the directions in your OEM Manual.

1. you will need a rebuild kit for each carb.

2. remove carbs trying not to disturb linkage adjustment.

3. dismantle carb, and place in carb clean solution, soak over night. ( do not put plastic parts in solution.

4. remove and clean the orifices (jets) high speed is usually behind the bowl drain plug, the slow usually top center of carb body, you will need special tool # 317002 to remove the orifices, or make your own. pictures below.

5 using compressed air. Blow out all orifices, with a small wire ( 2 or 3 stands of wire from an old extension cord) make sure all the jets are clear.

6. reassemble the carb body, with the carb up side dowm set the float parallel to the carb body.

7. complete reassembly,

8. take a clean piece of hose, connect to the fuel inlet, with the carb in operating position, blow into the hose, it should blow air out of the carb. now turn the carb upside

down, blow into hose, there should be no air allow thru. this means the float needle is seating, and stopping the flow, as it should.

9. reinstall, connect the linkage, and give it a try.

edit: the low speed is red arrow, the high speed is behind the bowl drain screw blue arrow.

Cleaning Carburetors First i ask you to follow the directions in your OEM Manual.

1. you will need a rebuild kit for each carb.

2. remove carbs trying not to disturb linkage adjustment.

3. dismantle carb, and place in carb clean solution, soak over night. ( do not put plastic parts in solution.

4. remove and clean the orifices (jets) high speed is usually behind the bowl drain plug, the slow usually top center of carb body, you will need special tool # 317002 to remove the orifices, or make your own. pictures below.

5 using compressed air. Blow out all orifices, with a small wire ( 2 or 3 stands of wire from an old extension cord) make sure all the jets are clear.

6. reassemble the carb body, with the carb up side dowm set the float parallel to the carb body.

7. complete reassembly,

8. take a clean piece of hose, connect to the fuel inlet, with the carb in operating position, blow into the hose, it should blow air out of the carb. now turn the carb upside

down, blow into hose, there should be no air allow thru. this means the float needle is seating, and stopping the flow, as it should.

9. reinstall, connect the linkage, and give it a try.

edit: the low speed is red arrow, the high speed is behind the bowl drain screw blue arrow.

Attachments

Last edited: