brooksville_rebel

Petty Officer 1st Class

- Joined

- Aug 12, 2011

- Messages

- 240

I went through the stickies and did some searches on the net but didn't seem to get an exact answer to my concern. This is a 24ft pontoon boat, wood floor.

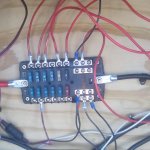

My front (bow) navigational lights need rewired. Currently they are wired with the negatives from each light wired to the negative back to the panel. Same with the positives. In the few diagrams I have viewed it seems to show each light going individually back to the panel or only one nav light.

Is that okay to wire like that or should each light be wired back on its own ? and if splicing is okay what's the best way to make those connections.? (I haven't unwrapped the current setup till I knew what was the proper way to wire them up to see how currently done and looks like its been rewired before so sure it was done the quick and cheap way

In my head I was thinking of putting a screw into the underneath and using a screw with washers and then put ring terminals on the wires and do it that way but again not sure its a good way or allowed to be done that way. Just want a hassle free, safe lasting rewire .

Thanks

Mark

My front (bow) navigational lights need rewired. Currently they are wired with the negatives from each light wired to the negative back to the panel. Same with the positives. In the few diagrams I have viewed it seems to show each light going individually back to the panel or only one nav light.

Is that okay to wire like that or should each light be wired back on its own ? and if splicing is okay what's the best way to make those connections.? (I haven't unwrapped the current setup till I knew what was the proper way to wire them up to see how currently done and looks like its been rewired before so sure it was done the quick and cheap way

In my head I was thinking of putting a screw into the underneath and using a screw with washers and then put ring terminals on the wires and do it that way but again not sure its a good way or allowed to be done that way. Just want a hassle free, safe lasting rewire .

Thanks

Mark