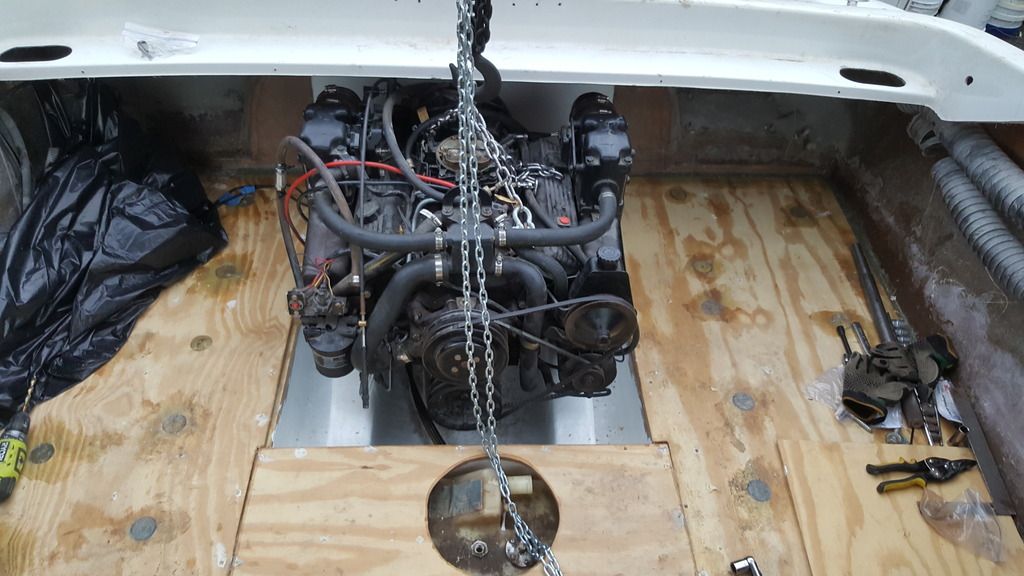

Hey everyone. I have been MIA for a while. I did not work on the boat last year at all. As you can see in my posts I had to work on it outside at our rental house so I wasn't able to do anything with it in the winter. So I built a cradle for it to put it in a friend's garage to try to work on it through last winter.

Well lots of things have changed for me and my new family. Last winter we spent a few months and bought my wife a jeep, we learned we were pregnant so se started looking for a house to buy. A few months later we bought a house in the mountains about 20 minutes closer to the lake so we can enjoy our boat when it is done. The house is awesome, it has an oversized 2 car garage so I can fit my workbenches and all my supplies along with the boat inside the garage. I purchased some LARGE 220v heaters for the garage so I could add some dry heat to keep it between 65 and 70 degrees while I work out there the rest of winter and spring. I rebuilt most of the boat trailer, such as new tires, rims, paint job, brake actuator, brake lines. New brakes and bearings will go on this spring. I also sold my diesel to get a gas truck since i wont be needing all the extra power to get over the mountain. The truck had a bad trsnsmission thst i was told about but the guy gave me a good deal on the truck. So i took on the task of rebuilding the transmission myself and it works great!!! Its a gmc suerra towmax with a 6 liter in it. I will attach all my pictures and pictures of where i am wuth the boat when I get to work. I am just excited to be back on the horse and on the final stretch.