I know everyone's first response is "hell no" but hear me out. I have 2001 Monterey 262 Cruiser that had a corroded aluminum fuel tank. A few things contributed to it. The prior owner never used the main switched bilge because it stopped working and relied on the backup bilge. This allowed water to routinely get higher in the bilge than it should, letting water enter the tank coffin. The limber hole in the tank coffin was set higher than the bottom of the enclosure so once water got it, it never got out.

Once water was around the fuel tank, it corroded and the aluminum oxide formed powder which mixed with water and became paste. This paste clogged the limber hold and the tank sat in this nasty stew, corroding it badly.

I was getting a fuel smell so I stuck my finger in the limber hold and a flood of nastiness came out.So, I removed the cabin floor and firewall panels and pulled the tank.

Thank God I did as the tank was just about to let go, I actually poked my finger through it.

This is what the tank looked like.

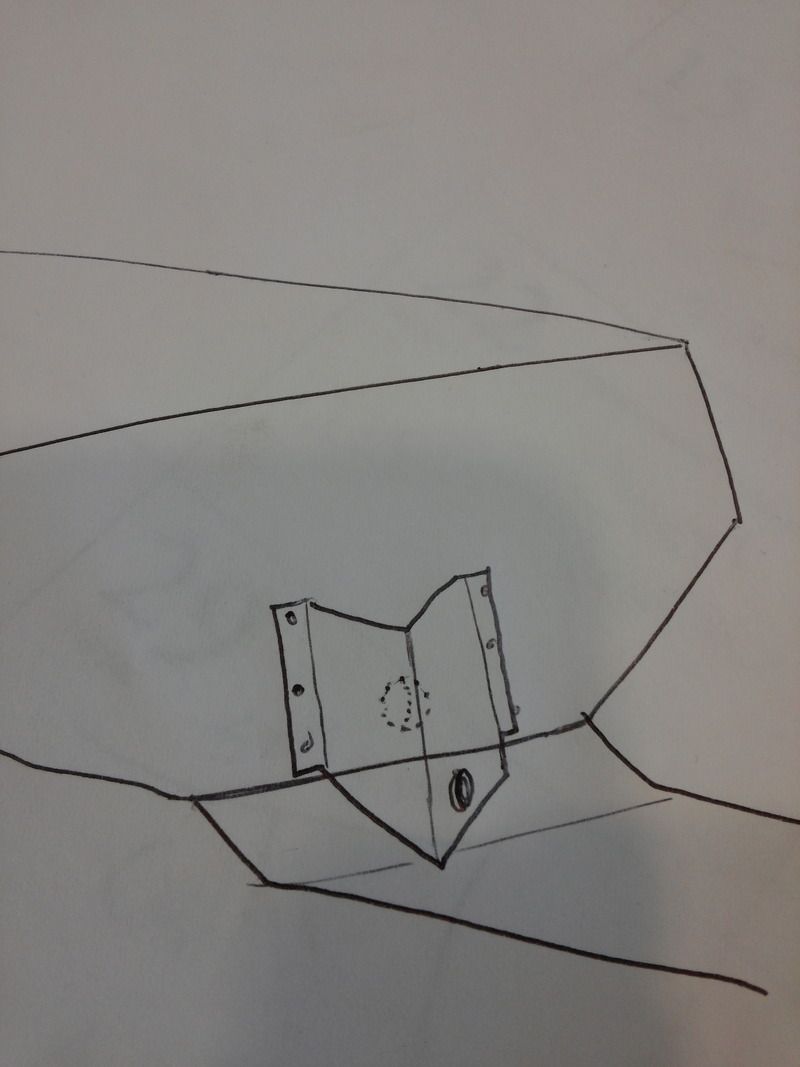

This mess is what the coffin looked like.

I vacuumed it and you can see the high water line and also see how the limber hole is mounted high.

I scrubbed it out with bleach and water and noticed it wasn't draining even with the boat tilted up.

Once water was around the fuel tank, it corroded and the aluminum oxide formed powder which mixed with water and became paste. This paste clogged the limber hold and the tank sat in this nasty stew, corroding it badly.

I was getting a fuel smell so I stuck my finger in the limber hold and a flood of nastiness came out.So, I removed the cabin floor and firewall panels and pulled the tank.

Thank God I did as the tank was just about to let go, I actually poked my finger through it.

This is what the tank looked like.

This mess is what the coffin looked like.

I vacuumed it and you can see the high water line and also see how the limber hole is mounted high.

I scrubbed it out with bleach and water and noticed it wasn't draining even with the boat tilted up.