Mr.Stickney

Petty Officer 3rd Class

- Joined

- Oct 1, 2014

- Messages

- 94

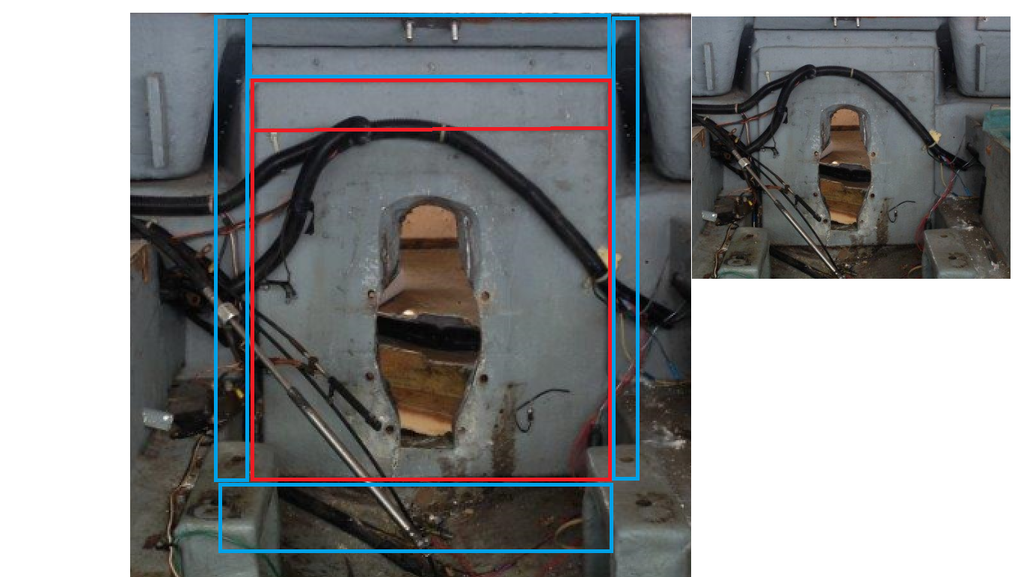

Ok, based on this pic of your transom, I'm assuming the following. The areas in red are the two layers of plywood to be replaced. The areas in blue will be the areas to be ground down and where the new glass tabbings will be applied to secure the new wood transom core in place. This should allow adequate bonding to the hull and secure the transom.

That would be a pretty good assumption. The transom actually extends to port and starboard in behind the jump seats right under the buckets for the swim platform. I have it ground out now but didn't get a chance to clean it so I didn't take any pictures yet. Will try and get some up tonight and get your thoughts on it.