59Hustler

Petty Officer 3rd Class

- Joined

- Jul 20, 2013

- Messages

- 82

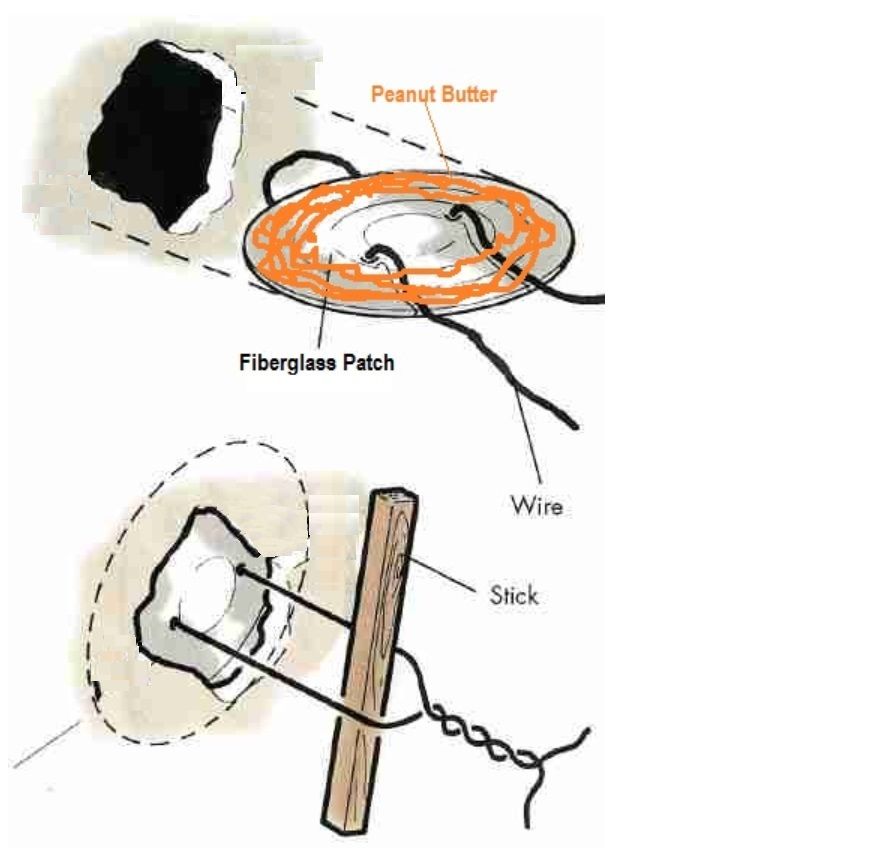

I found this hole well not really a hole but worn through spot on my keel just forward of the rear step or where the keel goes away this is on a 1959 Hustler 15 foot runabout. I have had the boat about 7 years and there were no marks on the bottom and she has always been solid. I found this when working on the rear roller of the trailer which is just aft of this spot..

My question is what is the best way to proceed with this repair?

My question is what is the best way to proceed with this repair?

Attachments

Last edited: