zool

Captain

- Joined

- Aug 19, 2012

- Messages

- 3,432

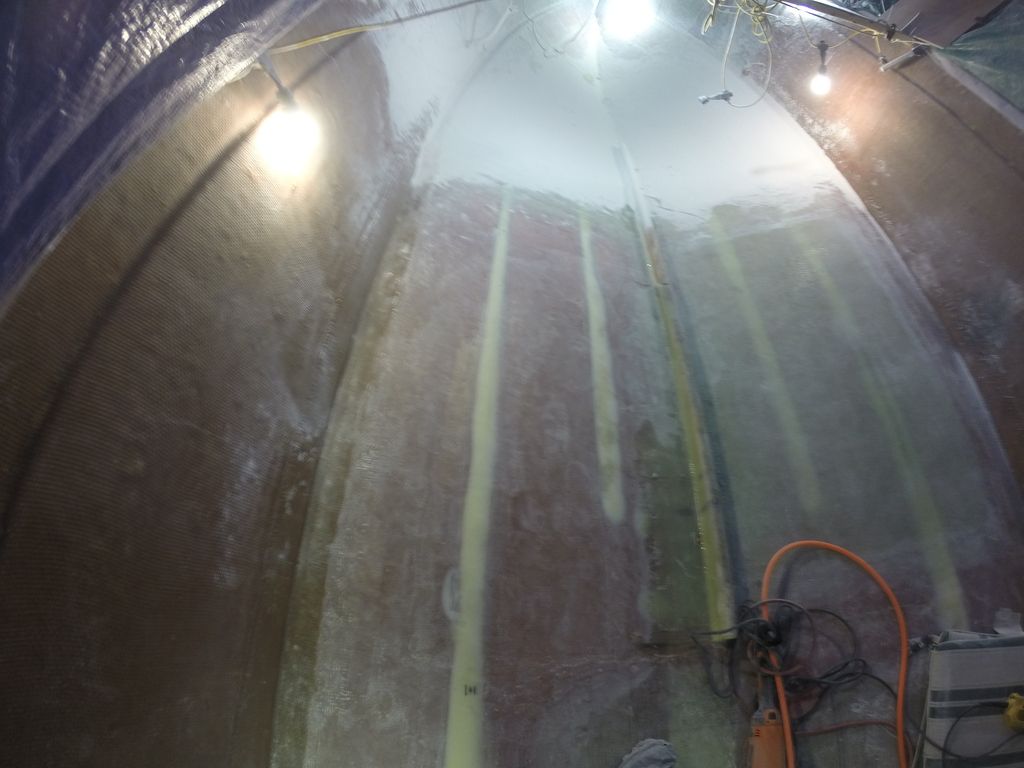

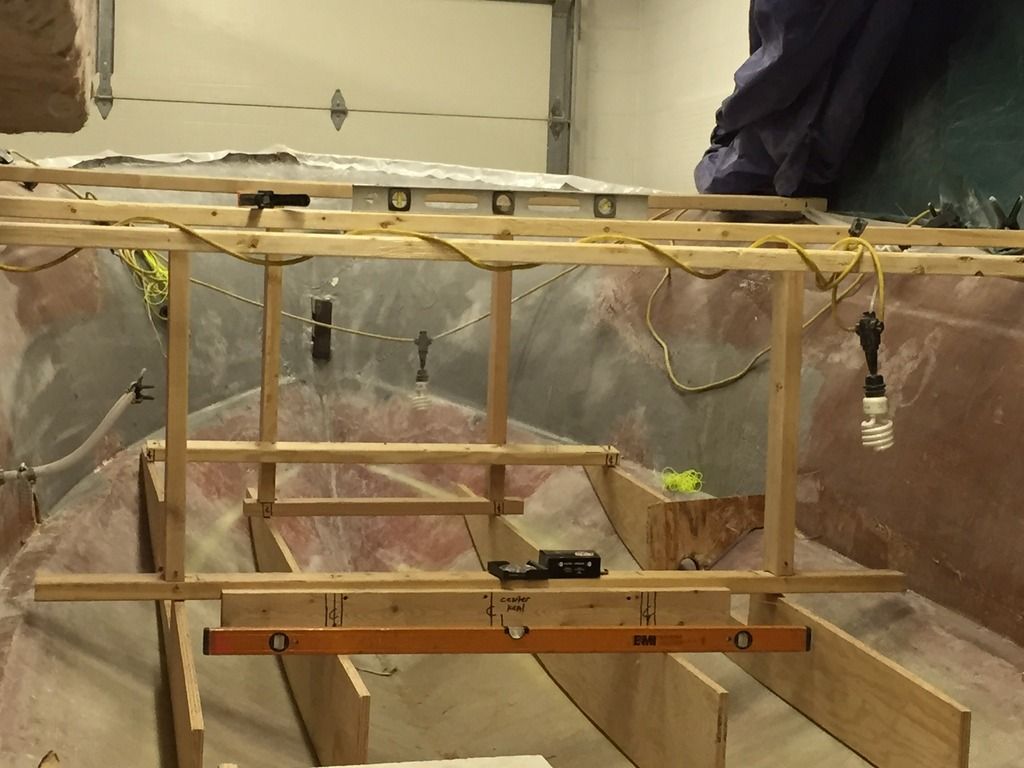

I agree with wog, 2 staggered layers of 170 biax and epoxy will hold up to anything reasonable in that 25, and will be stronger than the poly soaked roven that was there. If you want, have the schedule changed to use 3 layers of thinner cloth caps, draped down to the hull bottom, and staggered. The strength gain is significant.

I do that on mine, because I frequent nasty seas...

I do that on mine, because I frequent nasty seas...