Well it's been awhile since I?ve posted any progress, had another set back.

I'll start by posting the good stuff, it?ll probably help having to relive the bad.

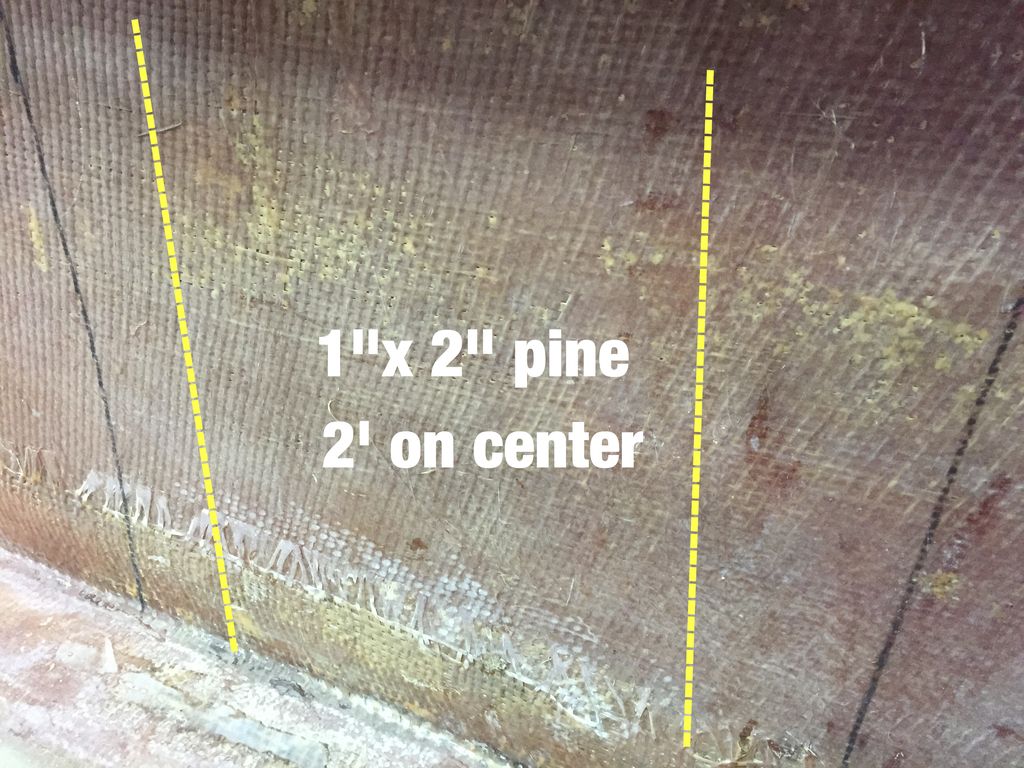

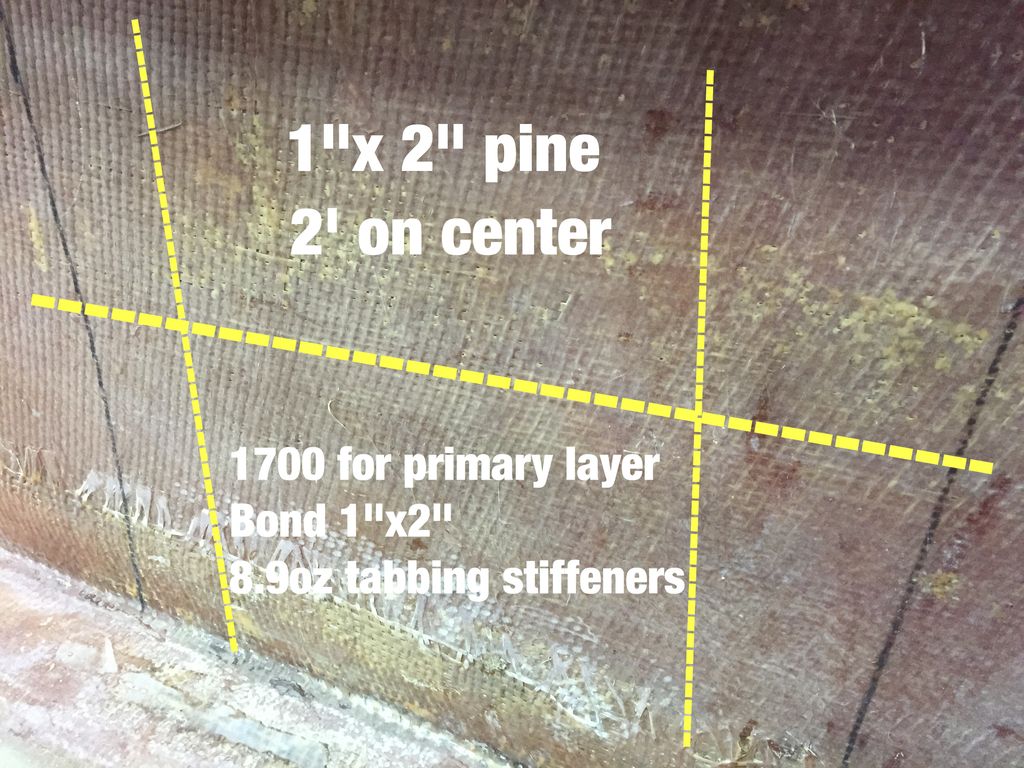

I'm seriously questioning my decision on the coarse I've taken on this project. My biggest hurdle that I'll never get over is the non stop, never ending discrepancies of how to build a boat. If you get 10 different boat builders in a room and tell them to write a glass schedule for a boat, you'll get 10 different glass schedules and methods of approach. Such as the world I guess.

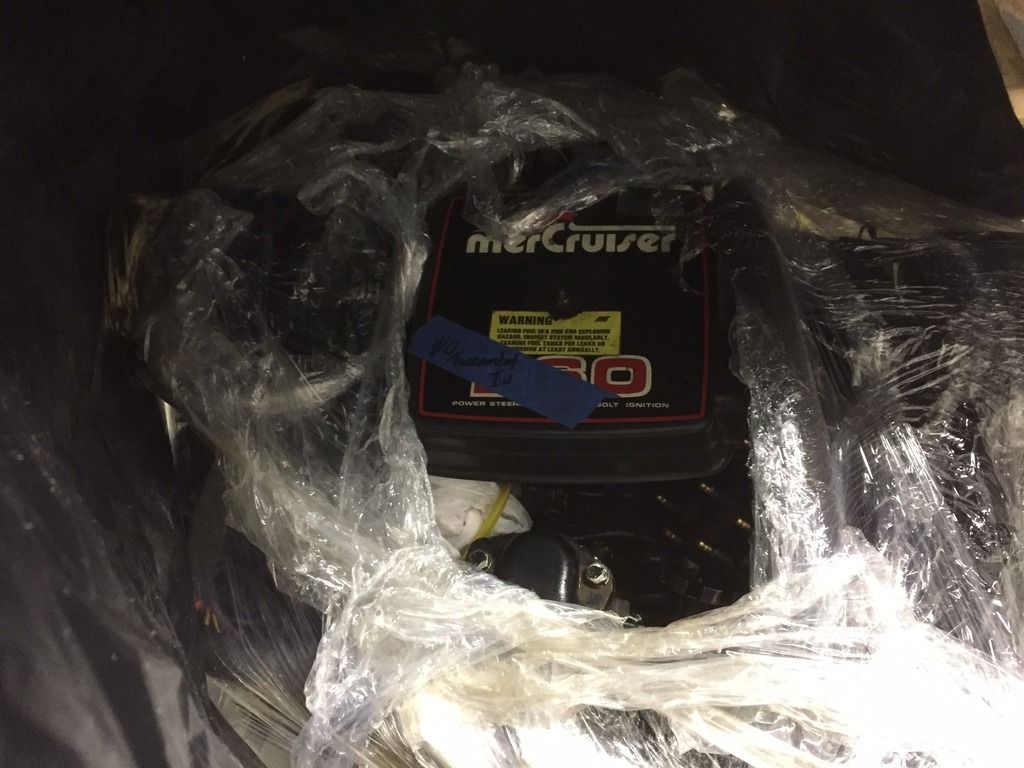

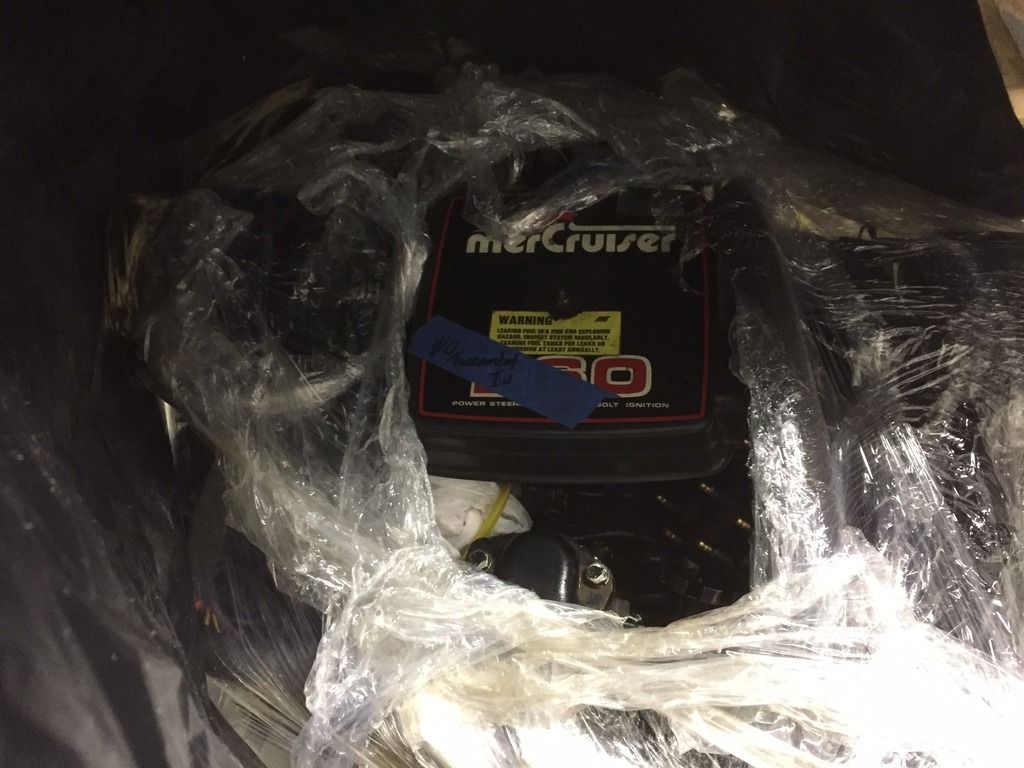

I had to pick up the motor and take it to the shop. I built a little dolly so I could move it around a little easier. I also covered it up with shipping wrap and left the top open so it could breath.

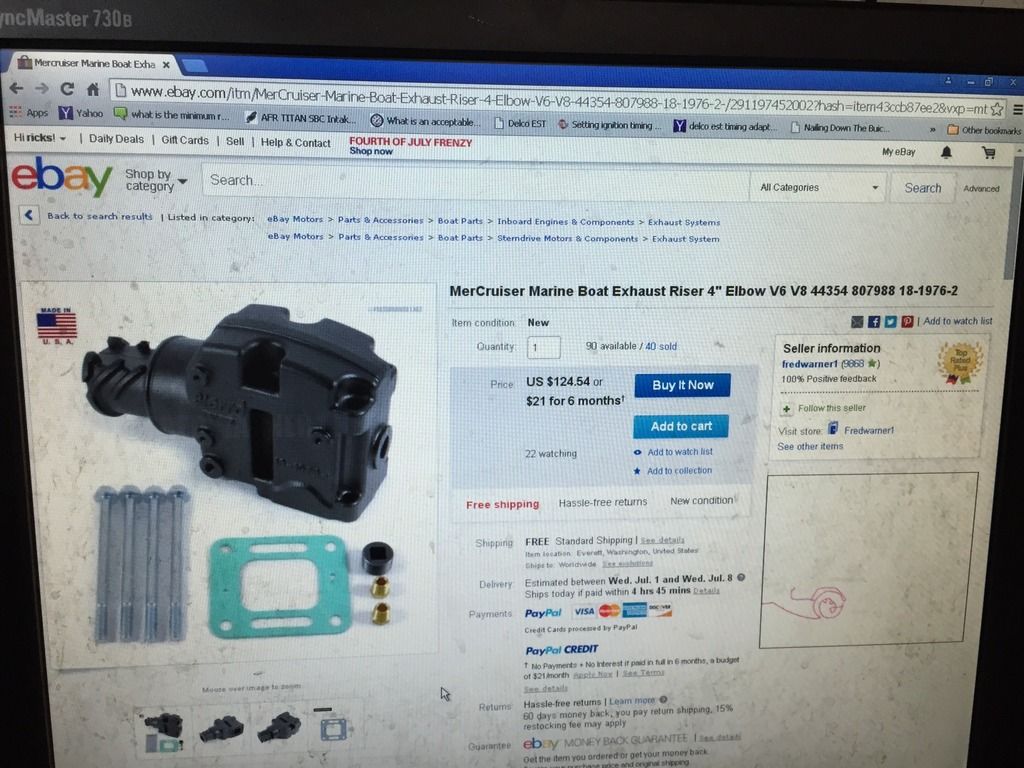

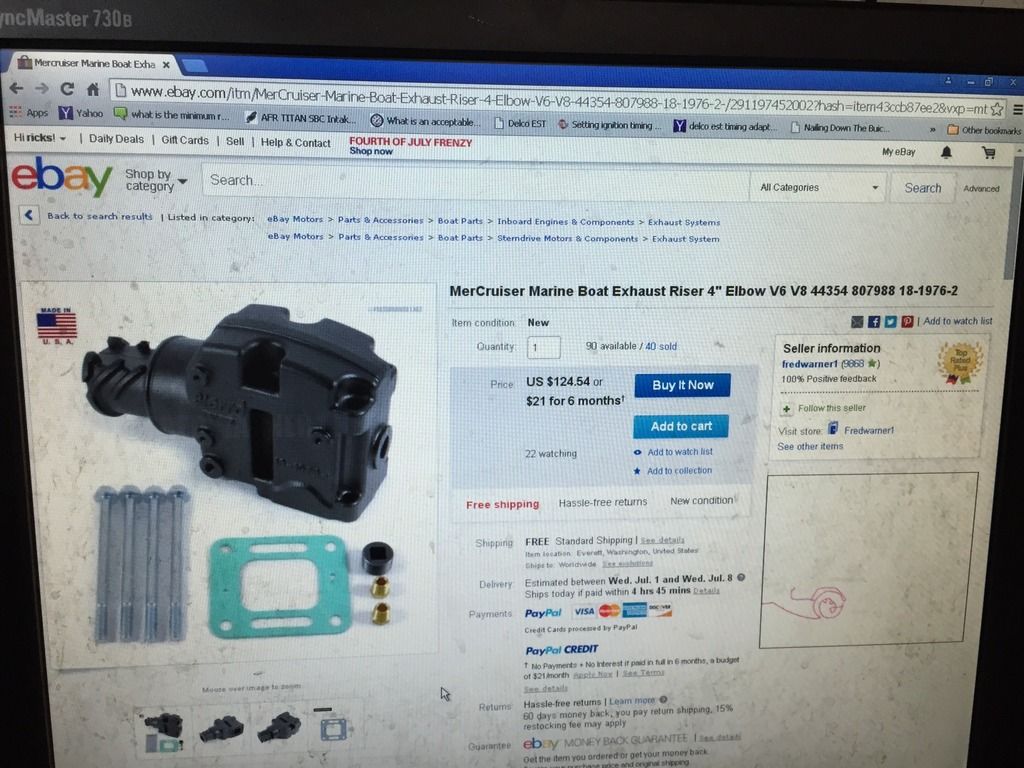

The shop I had it done rebuilt it completely top to bottom. While they were breaking it in, they noticed the motor was reverting water ( Still haven't looked in to what that exactly is ) and the cause was the manifold risers. Back in the 80s they used a few different risers, the ones I had didn't have enough pitch for the water to fully drain and he recommended changing them out to a better style.

Ricks Speedway Performance

46309 Telegraph Rd.

Amherst, Ohio 44001

Did an outstanding top of the line job!!!

And the shop owner is a really cool guy!!