PaulHaig123

Cadet

- Joined

- Aug 13, 2012

- Messages

- 10

Hello all,

I am looking for help / suggestions to repair my leaking tunnel hull, 21' Seabold Sidewinder.

Please see attached pictures.

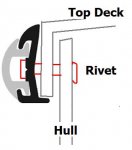

I have found that where the deck joins with the hull there are many places where water is able to penetrate.

When the rub rail is fastened it joins the deck and the hull with a rivet.

In the past someone has attempted to repair and drilled out the original rivets and replaced with larger rivets (resulting in larger holes through the deck and hull.)

For the repair of existing holes my thoughts where:

-drill out the holes

-clean with acetone

-fill holes (but I am not sure with what product to use here)

To reinstall rubrail and re-fasten the deck and hull my thoughts were:

-first install sealer in the gap between the deck and the hull (not sure what product to use here)

-drill new holes

-join the deck and hull by using screws + sealer (not sure what product to use here)

Any suggestions or guidance to existing posts that cover this topic would be much appreciated.

Paul.

I am looking for help / suggestions to repair my leaking tunnel hull, 21' Seabold Sidewinder.

Please see attached pictures.

I have found that where the deck joins with the hull there are many places where water is able to penetrate.

When the rub rail is fastened it joins the deck and the hull with a rivet.

In the past someone has attempted to repair and drilled out the original rivets and replaced with larger rivets (resulting in larger holes through the deck and hull.)

For the repair of existing holes my thoughts where:

-drill out the holes

-clean with acetone

-fill holes (but I am not sure with what product to use here)

To reinstall rubrail and re-fasten the deck and hull my thoughts were:

-first install sealer in the gap between the deck and the hull (not sure what product to use here)

-drill new holes

-join the deck and hull by using screws + sealer (not sure what product to use here)

Any suggestions or guidance to existing posts that cover this topic would be much appreciated.

Paul.