We came to the same conclusion on the transom. I do like the idea of making a proper bilge area, which i guess showed up a few years later.

That brings up a couple of questions:

1. Thoughts on using foam on these older designs. Again, I've read both sides as i was researching.

Flotation foam is good insurance in many ways. For your personal safety and that of your passengers. For your boat and for your wallet. It costs a lot of money in fines and recovery costs to get a boat up off the bottom of a body of water. You are NOT required to put it in, but IMHO you should seriously consider doing so.

2. When screwing the deck down, even filling the holes with silicone before screwing them in, can't this compromise the integrity of the stringers water resistance?

I wouldn't recommend using silicone but I would recommend predrilling and filling the holes and coating the screws with resin. You are correct in that any penetrations create points of entry for water but proper care and maintenance along with proper installation techniques should greatly minimize the possibilities.

3. If the stringers and deck are watertight, and there is a separated bilge area, if water were to get under the deck, how does one get rid of it? I guess I am confused by the design. The Seafair originally had an open area under the stringers that would empty at the gabbard drain. If i build my bilge there i am stopping this path.

You drill drain holes in the bilge and limber holes in your stringers to allow water to drain that's under the deck into the bilge when the boat is stored bow up.

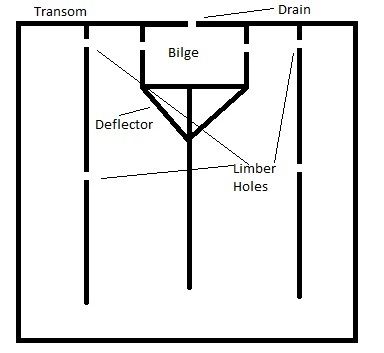

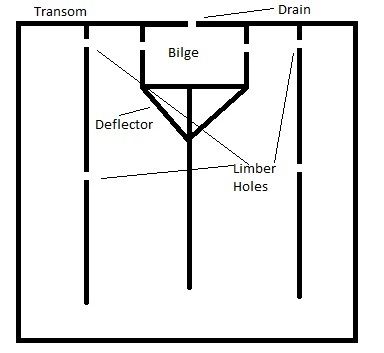

Something similar to this drawing...

You plug the drains when not in use and then pull them when the boat is stored bow up. Any water under the deck will flow into the bilge and emptied thru the transom drain.

You plug the drains when not in use and then pull them when the boat is stored bow up. Any water under the deck will flow into the bilge and emptied thru the transom drain.