wow- thanks guys and now ill answer the questions:

1- transom going all the way down to bottom- see that was my thought process is that it would be stronger, didn't think much about water since it was encases in epoxy- makes perfect6 sense- ill cut it to bottom out at the floor

2- transom is sticking above spashwell because the strigers were in the way- I cut grooves to go over the stringes and was going to epoxy the stringers in and also bolt original knee plates to wood. This will no longer be required since Ill cut the transon to end at floor instead of going all the way to the bottom

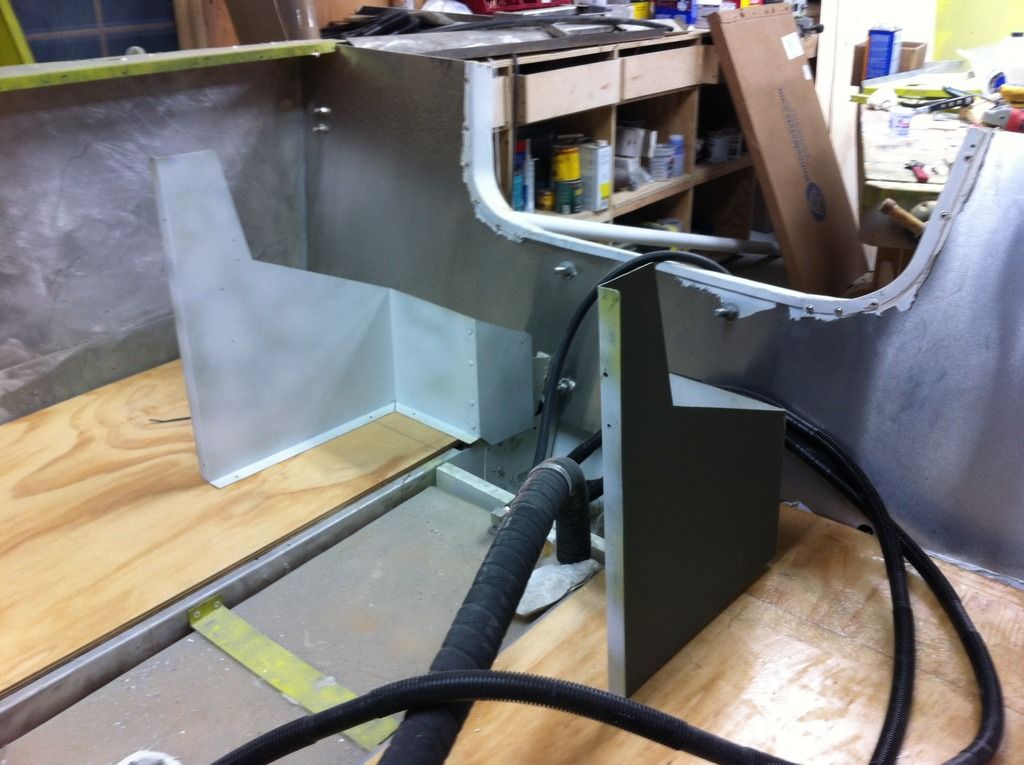

3. splashwell is not being deleted, just made smaller, with storage cabinets on the sides to the hull. I suspect structurelly this will be stronger than just the splashwell going all the way across. They way the original was designed will still be basically the same, except instead of dipping down for the splashwell on the side- I would keep full height

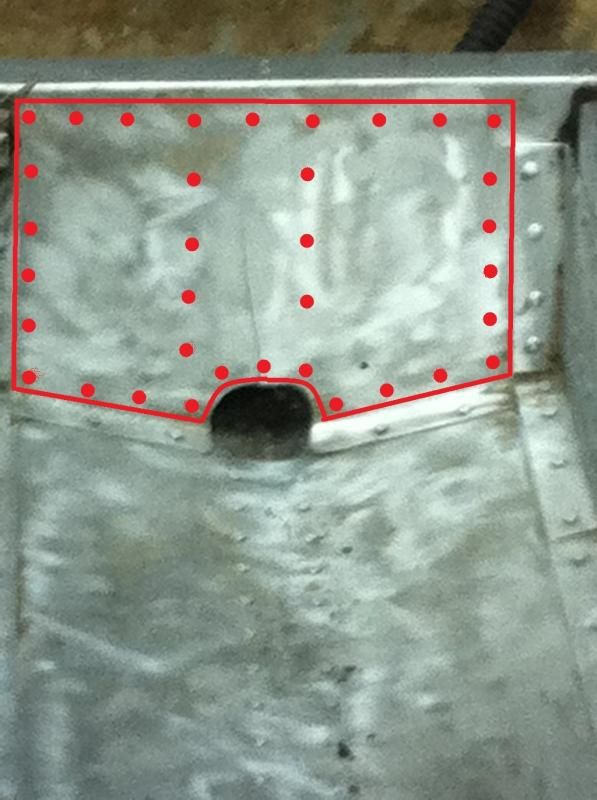

4. I used Clecos to hold metal in place before riveting- the only metal used in the boat is 5052 aluminum and 2117 rivets- no steel, copper, or any other metal or shavings

5. transom will be attached as original- knee braces to sringes0 1/4 2117 rivets, motor mount thru and thru, drain holes for smaller splashwell (press formed_ thru and thru- should I use some 5200? that would make it a bear to get out if needed.

I made a "ladder" frame last night for the gas tank- original as just two light strips on the sides and livewell hoses running underneath tank- which crashed them years ago. thought was to 5200 the gas tank to the ladder that is rivewted- i did not have room to use the method on a prior post to install the tank.

That yellowish stuff you see is Gluvit on all seams and rivets. you can see the slightly darker color as well up in the bow

This is my first shot at boat restoration, I truely appreciate the feedback