Seadoomanls

Petty Officer 3rd Class

- Joined

- May 12, 2007

- Messages

- 83

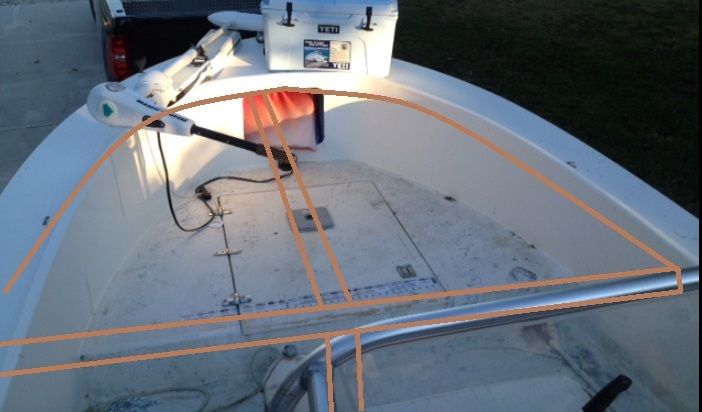

Hey guys! I am the proud owner of a completely out right owned 1974 Mako 20' Center Console. It is powered by a 1994 Yamaha 115 outboard that has served me well, with a few headaches of course. The purpose of this boat is 75% fishing, usually with myself and a buddy or two, and 25% pleasure cruise to an island where the very attractive misses would like to lay out in a bikini. Insert the problem here... The boat currently lacks a deck suitable for a 5'4'' person to lay out and get all the free sun rays available. I am attempting to attach pictures, and you can see in the front of the boat the deck goes up about 8" and is a 68"x49" deck. My idea here is to make the deck even with the top of the boat. This would make a great platform for me to cast net, fish from and attach the yeti for sight fishing. Also, it would double as a sun deck for the lady  . Hopefully my idea came out correctly.

. Hopefully my idea came out correctly.

My plan would be to frame the area using fiberglass covered 2x4's and a sheet of plywood up top. I am comfortable with fiberglass and gelcoat work, I would just need guidance on the BEST fiberglass cloth and resin to use for maximum durability. Also, I don't think it would add a bunch of weight, but maybe somewhere in the 100 lb area. I also attached a picture of a poling platform (37"x42") being sold locally for $200. My thought was to purchase it, cut the aluminum legs even, and use in as a removable casting deck on the existing front deck of the boat. This would suit my needs for fishing, but wouldn't help with the sun deck idea.

I would really like to bring the deck up even to the top of the boat, as this would be my ideal situation so long as it doesn't cause a rot issue or a weight issue. Also, I have all the free wood I can get my hands on, so it would only cost fiberglass materials. My time is valued very high, but I give it to myself for free .

.

Thanks!

My plan would be to frame the area using fiberglass covered 2x4's and a sheet of plywood up top. I am comfortable with fiberglass and gelcoat work, I would just need guidance on the BEST fiberglass cloth and resin to use for maximum durability. Also, I don't think it would add a bunch of weight, but maybe somewhere in the 100 lb area. I also attached a picture of a poling platform (37"x42") being sold locally for $200. My thought was to purchase it, cut the aluminum legs even, and use in as a removable casting deck on the existing front deck of the boat. This would suit my needs for fishing, but wouldn't help with the sun deck idea.

I would really like to bring the deck up even to the top of the boat, as this would be my ideal situation so long as it doesn't cause a rot issue or a weight issue. Also, I have all the free wood I can get my hands on, so it would only cost fiberglass materials. My time is valued very high, but I give it to myself for free

Thanks!