Barramundi NQ

Petty Officer 1st Class

- Joined

- Jul 3, 2014

- Messages

- 342

question regarding the cradle rickryder mentioned.....Do I need to support the hull more than the rollers on the trailer]

Nice thread! Just gonna hope in and follow along. If'n I may?

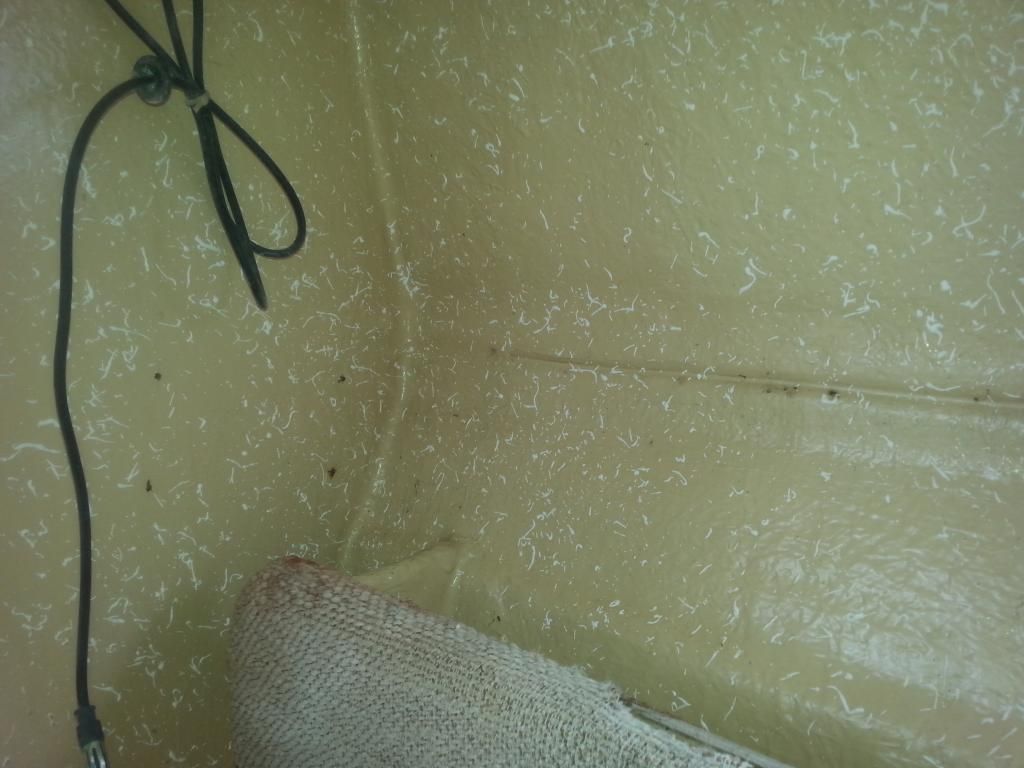

Yes especially on a roller trailer...a bunk would carry more of the load where the rollers are pressing on smaller points. When you remove all the stringers and bulkheads you have a fiberglass shell and the rollers could indent the hull...this is a good link to some ideas what you can do http://forums.iboats.com/forum/boat...-and-hull-repair/599028-boat-hull-cradle-help

Extra support for a roller?

Or, if it's near the transom, maybe the same hull was used for an inboard motor?

You have to think they wouldn't do that for no reason.

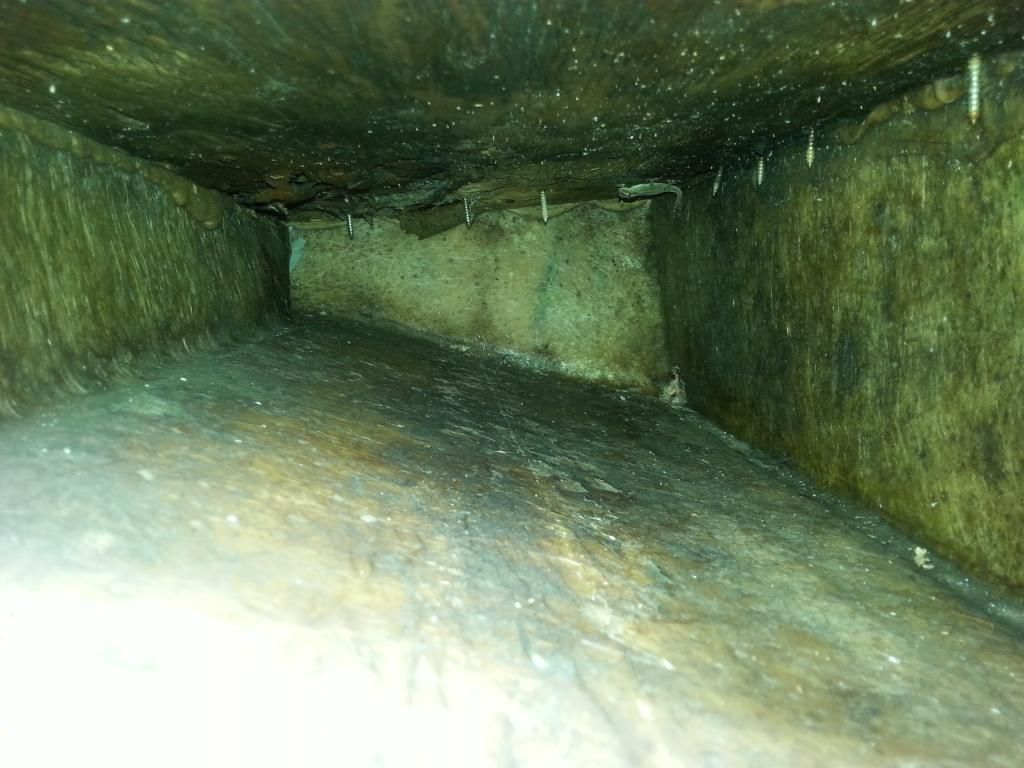

Ok I have big question. Do I need to decapitate her? Is there a alternative way to acces the transom without taking the cap off? I'm seriously considering putting a pod on the back the add around 600mm (2 feet) in overall length. This would mean removal of the splashwell (throw it away) and I gain that area as floor space and maybe a fold down seat.

I would appreciate some input here before I take a saw to her.....

Cheers from Tropical Australia!