fisheymikey

Chief Petty Officer

- Joined

- Jul 30, 2012

- Messages

- 450

there was a piece of pine exceeding like a little stringer and glass over it

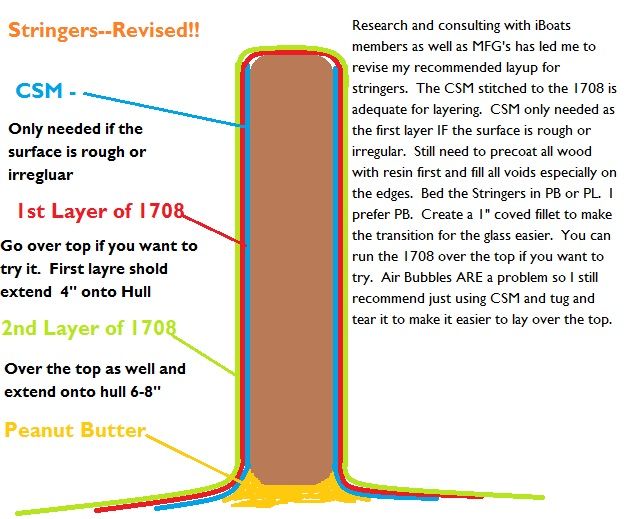

Hi everyone here is my setup for tomorrows stringer instalation. i will be using PL for the glueing to the hull.

hope someone chimes in before tomorrow morning. i currently have a force 125 that runs good but maybe i want to upgrade to a 135 optimax the difference of weight is about 120lbs it seems to me a huge difference would my new transom have enough strength to endure the oceans waves? also im having a buddy of mine making me a "armstrong" bracket type. i figure its going to weigh another 50-60lbs.

i feel the weight is pretty significant.. any suggestion will be greatly appreciated

I would definitely overbuild the crap out of transom... IMO Bayliner did not build in a lot of margin. I have the same concern. At some point my FrankenChrysler will need to be replaced and the modern engines are, bizarrely, so much heavier.

Weight is going to be a bigger factor than horsepower. The other thing you'll need to consider is centre of gravity. You might want to consider ways to move some weight forward to compensate.

BTW, what year is your Force? If it's early enough there may be a lot of parts in common with my FrankenChrysler. If you're going to sell it let me know.

Yup, I;d recommend capping them with a layer of Tug and torn CSM.

Same with EEEpoxy application? Just wondering.That csm drives me crazy! Might just, if I have to based on your reply cut a strip of 1700, glass it to the top of the stringer then grind off the rough edges, then pb stringers to deck.