Over the last couple of days, I rebuilt my stringers and finished up two bulkheads, coated everything in resin and bedded it all in PB. Also picked up 2x2s that will serve as cleats and coated them in resin. Recorded a video update, but still trying to work out the kinks with the new camera so I can get it posted. In the meantime, here are just a few pics of where I left off earlier today. Let me know what you all think of the fillets. At this point I am considering adding to them so they extend further up the sides of the stringers and provide a softer transition for the glass from stringer to hull. Then again, maybe they're fine.

Used temporary spacers to keep the stringers positioned correctly. Will remove spacers before cutting them to height.

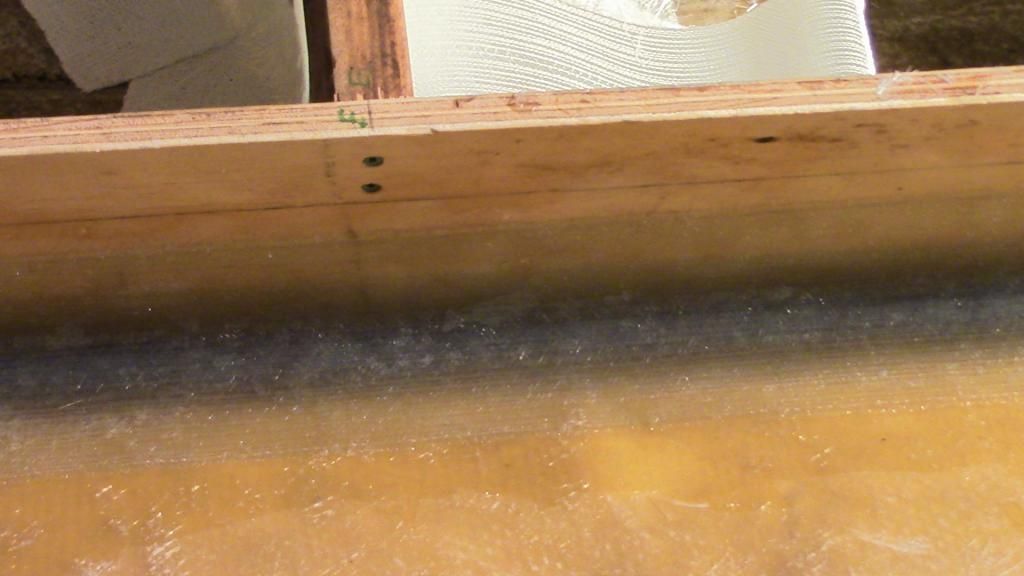

Close up of my PB

Rear stringer box is already cut to height.

View from front looking to rear