I have a laundry list of things I need to do so (hopefully) I have a trouble free 2015.

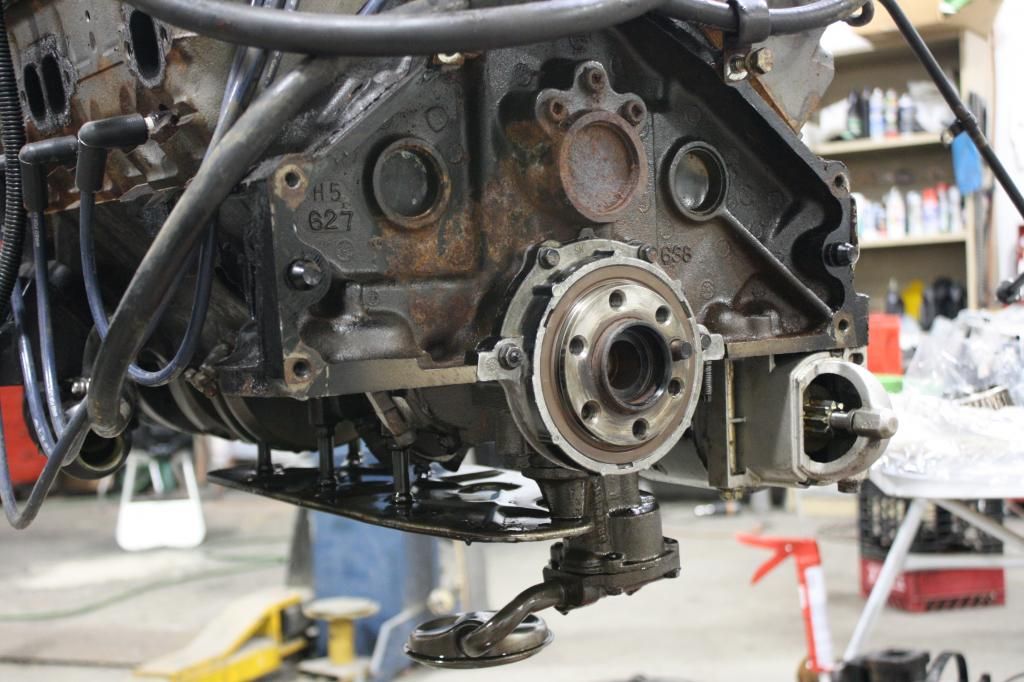

New cables, t-stat housing, bellows, speedo tube, blower and hoses, fuel fill hose (replaced the breather and fuel line already), manifolds and risers, rip out the stinky carpet and paint and just clean up the whole engine compartment. I have pull the engine and check/replace the oil pan and possibly rear main seal. New exhaust flappers too.

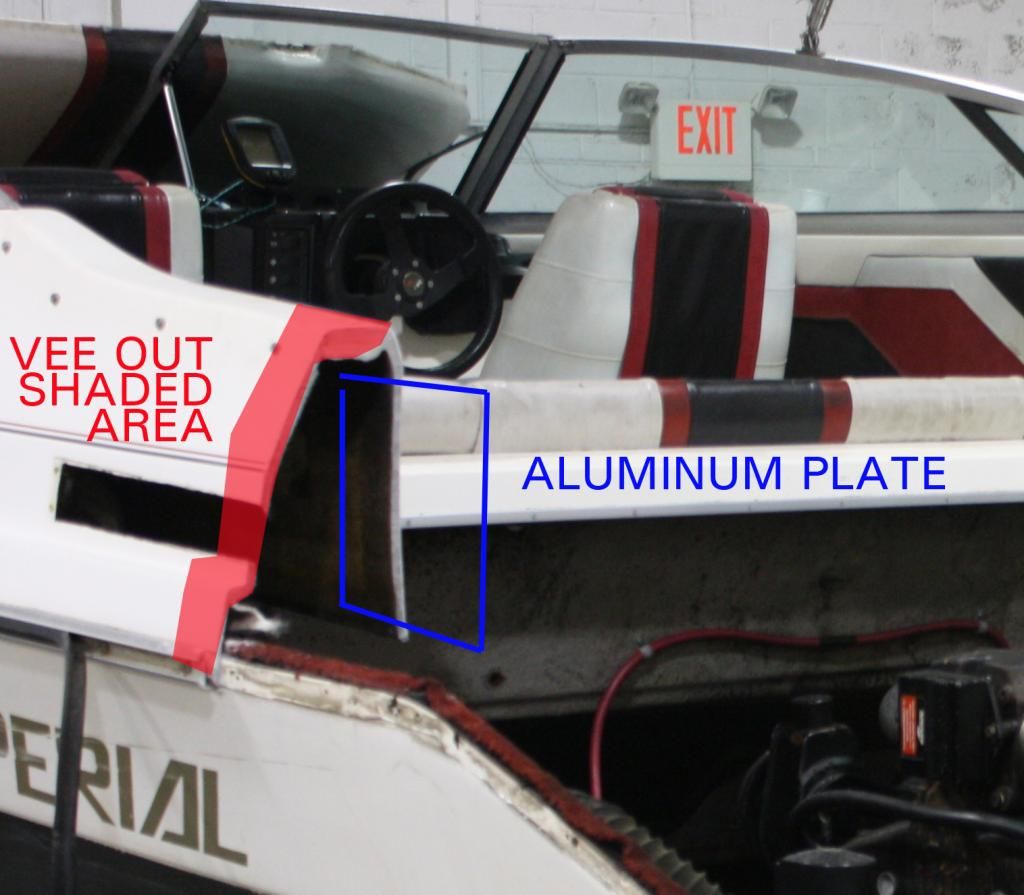

I also have some play on the gimbal ring, a little left to right and about 1/8" up and down. Can you replace the pin w/o removing the whole gimbal housing? I'm going to try to tighten up the bolts first.

What's the paint used for bilges?

New cables, t-stat housing, bellows, speedo tube, blower and hoses, fuel fill hose (replaced the breather and fuel line already), manifolds and risers, rip out the stinky carpet and paint and just clean up the whole engine compartment. I have pull the engine and check/replace the oil pan and possibly rear main seal. New exhaust flappers too.

I also have some play on the gimbal ring, a little left to right and about 1/8" up and down. Can you replace the pin w/o removing the whole gimbal housing? I'm going to try to tighten up the bolts first.

What's the paint used for bilges?