First off, you can never ask enough questions when it comes to this crazy bizness of boat restoration...I totally agree and back up woody's suggestions 99.9% of the time, but sometimes there are other ways to accomplish the same things...it just takes a bit of time to get around to posting the answers...

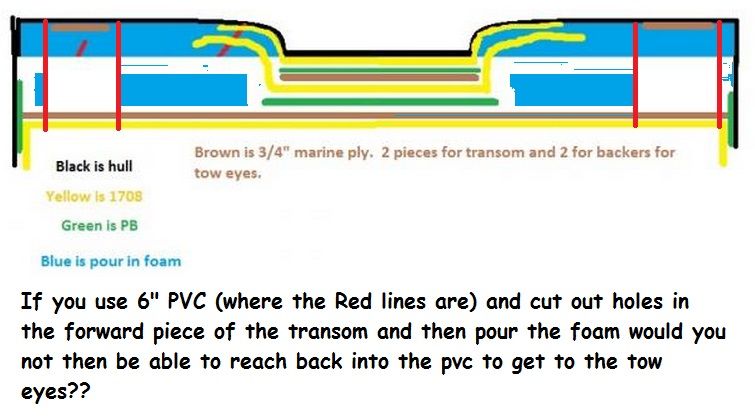

As for the reconstruction of the transom, I would basically stick with the way it was originally done, except I would take it to the iboats level and PB it in solid to the outer skin of the hull in the center and all along the "floating" edges, then fill the empty spaces with foam...tab everything in nice and solid, then lay on a layer or two of 1708 to lock it all in...

With the cross brace and knee stringers properly done up, it will be battleship strong!

As for the deck height, I have come to learn that most old boats are built to the "

Good Enough" scale...nothing is ever precisely the same measurement from one side to the other, front to back, or top to bottom...I have seen discrepancies as much as 1 inch from one to another...

Obviously we are blessed with ADD, OCD and a host of other disorders that force us to restore our boats to better than factory new condition and therefore tend to over stress and over think each and every step we take...

My humble opinion is that if you are going back to what was originally there, you can fudge things a little here and there and still end up with a much better product than original...

If you want your deck to be close to the original height, or if you want your deck to be sloped front to back, or dipped towards the middle or the edges, this is the time to decide...

The factory built them to make a profit and stuck with what was efficient and got the finished product out the door as quickly as possible...not necessarily what was absolutely best for the particular design of the boat...

Now that you have a "blank canvas" to work with, you are free to make some alterations and changes as you see fit, as long as you stay within the basic parameters of the original design...

I am a creature of thinking that sometimes I know more than the guys that originally designed certain things and I always feel like I can improve on the original, so for what its worth, do what you feel will work for you...without going too crazee!

Happy Camel Day!