Re: Advice Needed on Prepping and Painting an Alum. Boat

gm280, way to put my trailer to shame. Truly inspirational stuff right there. You listed your comp.'s HP but not the gallon capacity though. I agree with you about prep. I am a finish carpenter/ house painter and I prep prep prep. My customers are usually ticked at me because they don't see the progress until the last day or so. If you prep right, the painting just flies. I consider this thread prep too. I want to know exactly what to do and not to do.

Wood, Thanks for the input. I have read your whole BF thread and read hundreds of your always helpful replies on many a thread. I am a bit concerned with this compressor for the reasons you listed. The problem I have is the budget. I can't see spending four or five hundred on a tool that will paint this boat and blow out my sprinklers once a year. lol, I'm sure it will get a bit more use than that but not enough to justify the investment. I am also planning on leaving this boat in the water for the season so, as per your $100 dollar process, I cannot use rutso. Which I think means imron or awl grip will be used? I Think this means spraying is my only option. What do you think of my piggy back idea? HF has a 7 gal. air tank on special in one of their 5 ads this week for cheap. I thought that was a cost effective way to get my set up to 32 gals. I have a 4 hp 25 gallon compressor (craftsman if it matters).

Waterman, thank you. I agree with you and need this type of reply throughout this process. I am a perfectionist but I'm not going to paint the whole thing over if I find a bug in the finish. I am tarping my garage off(mostly to protect the firebird and other things also inside) with some 3 mil plastic I have left over from a job and will wet(dampen) down the floor to keep the dust to a minimum. I will also have a few box fans with a/c filters drawing air out of the space. I realize this is all I can reasonable due to prevent such things but I fully expect dust, bugs, and maybe some fish eyes. If I prep right I have done all I can do. I can't control the other stuff, not to mention my inexperience. Like I said before, I want any mistakes to be in the painting.

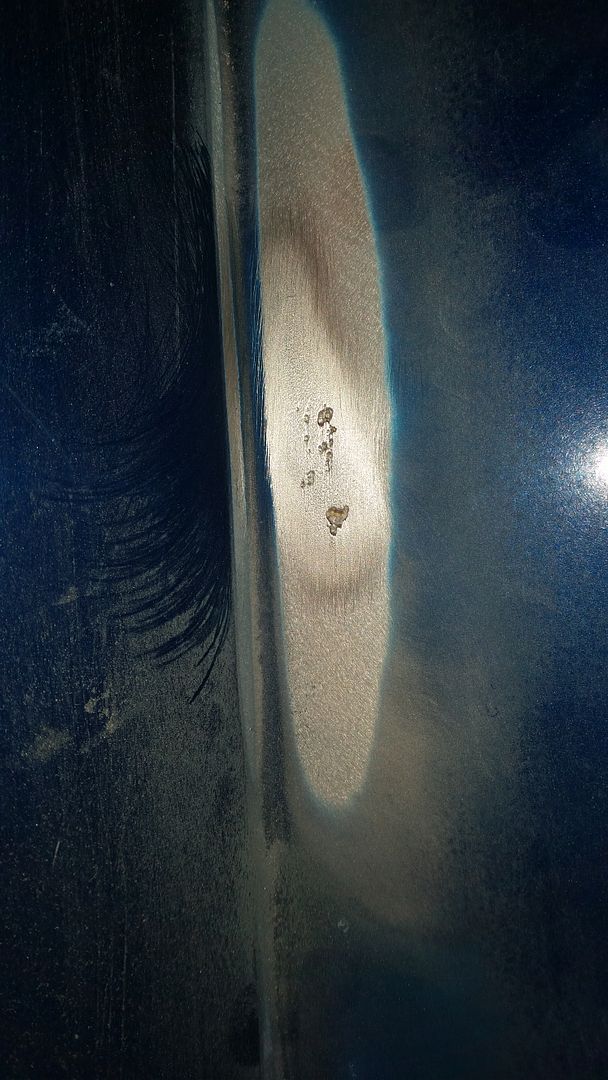

Thanks one and all for the help. I did get some work done over the week. I could only scratch about two hours out of the schedule but am happy with the progress. More pics tomorrow eve, Going to the Yankee game tomorrow with the wife, daughter and daughters friend. Should be a day full of popcorn, cotton candy ,hot pretzels and jumbo $17 sodas. I could have bought that compressor with what I will spend on junk tomorrow. but Hey, it's hat day...so I got that goin for me...which is nice.

gm280, way to put my trailer to shame. Truly inspirational stuff right there. You listed your comp.'s HP but not the gallon capacity though. I agree with you about prep. I am a finish carpenter/ house painter and I prep prep prep. My customers are usually ticked at me because they don't see the progress until the last day or so. If you prep right, the painting just flies. I consider this thread prep too. I want to know exactly what to do and not to do.

Wood, Thanks for the input. I have read your whole BF thread and read hundreds of your always helpful replies on many a thread. I am a bit concerned with this compressor for the reasons you listed. The problem I have is the budget. I can't see spending four or five hundred on a tool that will paint this boat and blow out my sprinklers once a year. lol, I'm sure it will get a bit more use than that but not enough to justify the investment. I am also planning on leaving this boat in the water for the season so, as per your $100 dollar process, I cannot use rutso. Which I think means imron or awl grip will be used? I Think this means spraying is my only option. What do you think of my piggy back idea? HF has a 7 gal. air tank on special in one of their 5 ads this week for cheap. I thought that was a cost effective way to get my set up to 32 gals. I have a 4 hp 25 gallon compressor (craftsman if it matters).

Waterman, thank you. I agree with you and need this type of reply throughout this process. I am a perfectionist but I'm not going to paint the whole thing over if I find a bug in the finish. I am tarping my garage off(mostly to protect the firebird and other things also inside) with some 3 mil plastic I have left over from a job and will wet(dampen) down the floor to keep the dust to a minimum. I will also have a few box fans with a/c filters drawing air out of the space. I realize this is all I can reasonable due to prevent such things but I fully expect dust, bugs, and maybe some fish eyes. If I prep right I have done all I can do. I can't control the other stuff, not to mention my inexperience. Like I said before, I want any mistakes to be in the painting.

Thanks one and all for the help. I did get some work done over the week. I could only scratch about two hours out of the schedule but am happy with the progress. More pics tomorrow eve, Going to the Yankee game tomorrow with the wife, daughter and daughters friend. Should be a day full of popcorn, cotton candy ,hot pretzels and jumbo $17 sodas. I could have bought that compressor with what I will spend on junk tomorrow. but Hey, it's hat day...so I got that goin for me...which is nice.