Joel_CA

Cadet

- Joined

- Sep 14, 2013

- Messages

- 16

Hi guys and gals,

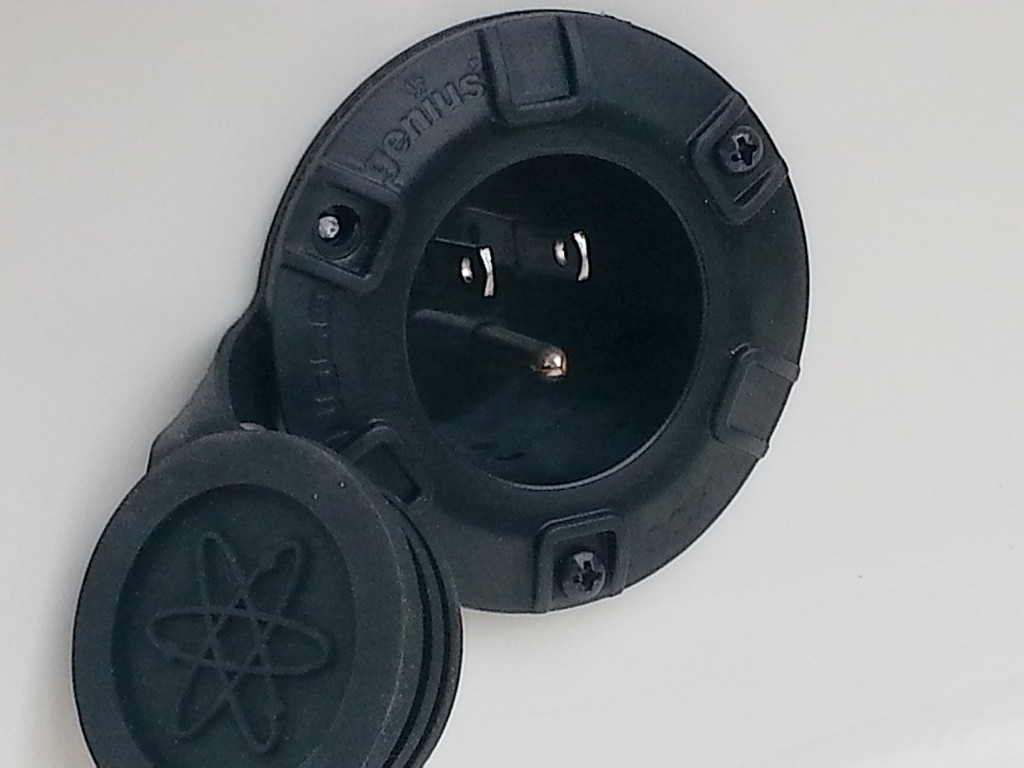

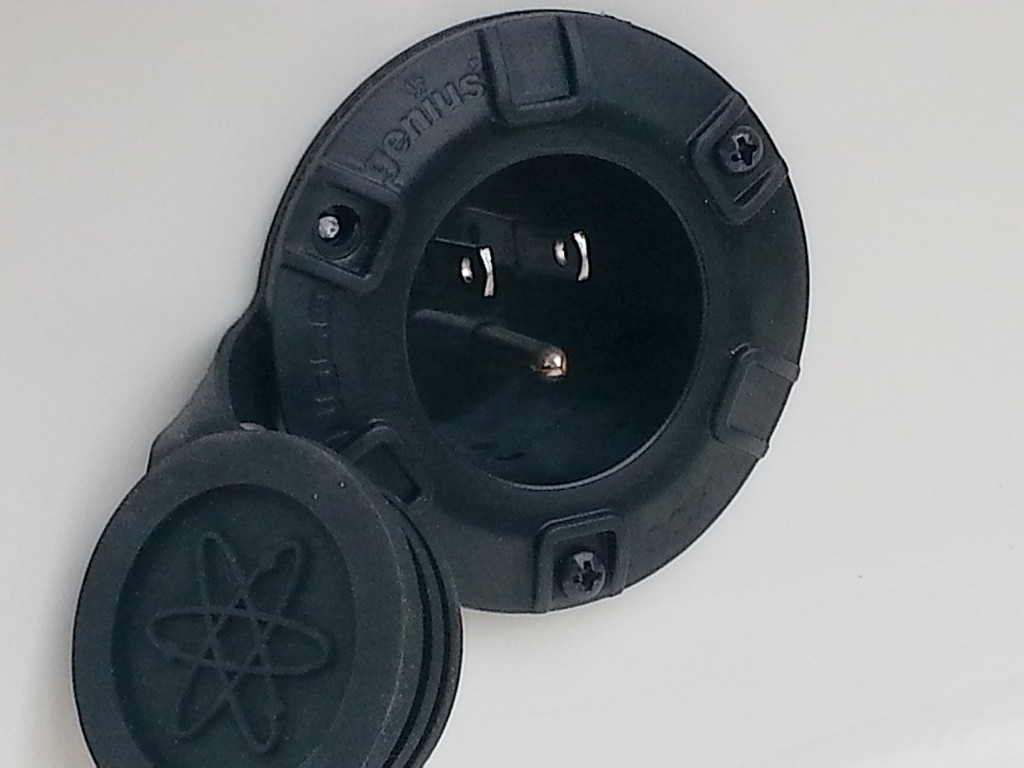

Im not sure if im in the right forum, but I was hoping some of you that might be in the middle of rebuilding, or have completed a rebuild, might have any experience with this. I was installing my new onboard battery charger (MinnKota MK 210D) and AC port plug (Noco Genius GCP1) when I ran into a little bit of trouble near the end of the installation. I had everything done and was admiring my new addition when I decided to replace the black screws that came with the GCP1 with some stainless steel screws. When I backed out the first screw, it immediately went soft and snapped in its place. The head sheared completely off. There appears to be about 1/8" of it still sticking out for me to work with but I won't know until I remove the other 2 and see whats left. Im expecting the same result with the remaining two screws. Any pointers on how to extract the broken screw(s) ? I was planning on taping off the area with masking tape and perhaps using a pair of vise grips and wishing for the best. Im just hoping someone can chime in on a less barbaric method that might be more of a sure thing. Any advice will surely be appreciated.

Thanks in advance!

Joel

Im not sure if im in the right forum, but I was hoping some of you that might be in the middle of rebuilding, or have completed a rebuild, might have any experience with this. I was installing my new onboard battery charger (MinnKota MK 210D) and AC port plug (Noco Genius GCP1) when I ran into a little bit of trouble near the end of the installation. I had everything done and was admiring my new addition when I decided to replace the black screws that came with the GCP1 with some stainless steel screws. When I backed out the first screw, it immediately went soft and snapped in its place. The head sheared completely off. There appears to be about 1/8" of it still sticking out for me to work with but I won't know until I remove the other 2 and see whats left. Im expecting the same result with the remaining two screws. Any pointers on how to extract the broken screw(s) ? I was planning on taping off the area with masking tape and perhaps using a pair of vise grips and wishing for the best. Im just hoping someone can chime in on a less barbaric method that might be more of a sure thing. Any advice will surely be appreciated.

Thanks in advance!

Joel