mr300z87

Senior Chief Petty Officer

- Joined

- Sep 15, 2010

- Messages

- 694

My friend has a 2002 Aquasport Exporer 250 and last year he noticed that one of the rear fish box hatches was soft. Last week when the weather got good here in NJ we climbed in to remove the hatch and this is what we found after some grinding.

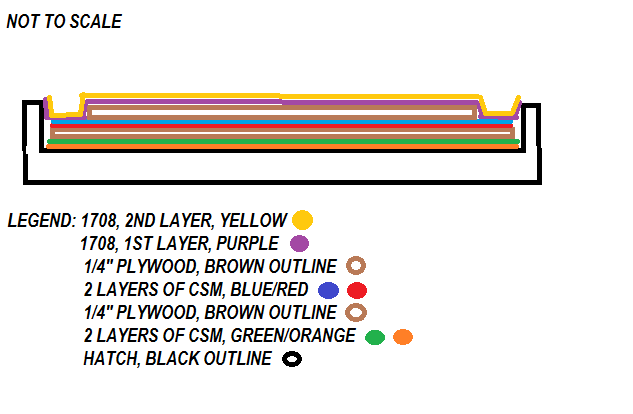

It seem that water got into the fastener hole and wicked up the plywood until it de-laminated and got soft. The construction is 3/32 of glass outside 1/4 in ply over the whole thing and then another layer 1/4 inch ply in the center 3/4s of the hatch and sealed up on with anoother 3/32 of glass. Wish is Took a photo before we started grinding. Since Auqasport has been out of business for a few years now finding a replacement has been tough we figured how hard can it be to fiberglass and repair it.

This is the outside of the hatch

I know we will need to grind out all the rotten plywood down to clean glass, but not sure where to go from there. My concern is how to glass up to the edge where it lay into the deck. Can anyone give me some recommendations as to how to proceed. We have some 1708 and US Composite poly resin not sure is this is the best stuff for this repair. This hatch needs to be strong as it is at the stern of the boat where a lot of fishing is done.

I have done some fiber glass work in years past although nothing like I have read about on this forum.

As always any help is greatly appreciated.

Mike

It seem that water got into the fastener hole and wicked up the plywood until it de-laminated and got soft. The construction is 3/32 of glass outside 1/4 in ply over the whole thing and then another layer 1/4 inch ply in the center 3/4s of the hatch and sealed up on with anoother 3/32 of glass. Wish is Took a photo before we started grinding. Since Auqasport has been out of business for a few years now finding a replacement has been tough we figured how hard can it be to fiberglass and repair it.

This is the outside of the hatch

I know we will need to grind out all the rotten plywood down to clean glass, but not sure where to go from there. My concern is how to glass up to the edge where it lay into the deck. Can anyone give me some recommendations as to how to proceed. We have some 1708 and US Composite poly resin not sure is this is the best stuff for this repair. This hatch needs to be strong as it is at the stern of the boat where a lot of fishing is done.

I have done some fiber glass work in years past although nothing like I have read about on this forum.

As always any help is greatly appreciated.

Mike

[/URL

[/URL